1. 裹包机核心解析:类型、原理与应用场景

1.1 裹包机基础认知:定义与核心作用

Pallet wrapping machines, commonly referred to as stretch wrappers or stretch hooders, automate the process of securing loads onto pallets or skids using stretch film or hooding material. The primary function is to create a stable, unitized load for safe and efficient transportation and storage. This automation replaces manual wrapping, significantly enhancing consistency, reducing material waste (film usage), and minimizing the risk of product damage and workplace injuries associated with manual handling. Consistent, optimal tension applied by the machine ensures loads remain intact despite vibration, shifting, and environmental factors during transit.

1.2 主流裹包机类型深度剖析

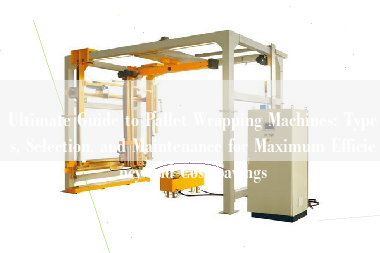

Three primary designs dominate the industrial pallet wrapping landscape, each suited to specific operational needs:

- Turntable Wrappers (托盘式): The most common type. The loaded pallet sits on a rotating turntable. A vertically moving film carriage (film carriage) dispenses stretch film as it travels up and down the height of the load while the turntable rotates. Ideal for stable, uniform loads at moderate to high throughputs. Variations include basic semi-automatic models requiring operator pallet placement/removal and fully automatic models integrated into conveyor lines.

- Orbital Arm Wrappers (悬臂式/旋臂式): The pallet remains stationary. A large rotating arm, carrying the film carriage, orbits around the stationary load, dispensing film. Essential for wrapping extremely heavy, unstable, or oversized loads that cannot be placed on a turntable (e.g., large machinery, building materials, awkwardly shaped items). Offers excellent stability for challenging loads. Often configured as “semi” units requiring a forklift.

- Rotary Ring Wrappers (环体式): The film carriage is mounted on a large, fixed ring structure encircling the wrapping zone. The loaded pallet moves through the center of the ring on a conveyor. As the pallet moves forward, the ring rotates, wrapping the film around the load. Designed for very high-speed, continuous operation in fully integrated production or distribution lines. Offers the fastest cycle times for standard pallet loads. Requires consistent load presentation via conveyor.

1.3 核心工作原理与技术参数详解

The fundamental operation involves controlled film dispensing under precise tension. Key steps include:

- Film Clamping & Tail Cutting: The film end is secured to the load.

- Pre-Stretching (Critical Feature): Most machines incorporate pre-stretch rollers. These rollers stretch the film before it reaches the load, typically achieving 200-300% stretch. Pre-stretching maximizes film yield (reducing film cost per load), improves load containment force, and enhances puncture resistance.

- Wrapping Pattern: The machine executes a programmed pattern combining rotation (turntable or arm) and vertical movement (carriage or ring rotation relative to load height). Patterns include spiral, roping, and customized configurations to optimize containment for specific load types.

- Film Cutting & Sealing: At cycle end, the film is cut and sealed (often melted) to the load.

- Top Sheet/Web Application (Optional): Some models can apply a top sheet or web for additional dust/moisture protection.

Critical Technical Parameters:

Load Dimensions: Max/Min Pallet Size (W x D x H).

Load Weight Capacity: Max weight the machine can handle (turntable max load or arm stability limit).

Throughput (Pallets/Hr): Cycle time dictates maximum output.

Pre-Stretch Ratio: Percentage of stretch applied (e.g., 250%).

Film Roll Size: Max core diameter and roll width/weight accommodated.

Power Requirements: Voltage (e.g., 480V 3Ph), Amperage.

Control System: PLC type, HMI interface, programmability, connectivity (Ethernet/IP, Modbus).

Safety Features: E-Stops, light curtains, safety interlocks.

1.4 关键应用场景与行业适配指南

Pallet wrappers are ubiquitous across industries shipping palletized goods:

- Food & Beverage: Securing boxes, cans, bottles. Hygiene is critical; stainless steel construction and washdown capabilities (IP ratings) are often required. High-speed rotary rings common.

- Pharma & Healthcare: Similar needs to Food & Bev regarding hygiene and material traceability. Precision wrapping protects sensitive products.

- Chemical & Plastics: Often involves heavy drums, bags, or irregular items. Orbital arm wrappers excel here. Potential need for explosion-proof (EX) rated equipment in certain environments.

- Logistics & Distribution Centers (DCs): High-volume, diverse load types. Turntable and rotary ring wrappers dominate, integrated into sortation systems. Focus on speed and reliability.

- Building Materials/Construction: Heavy, bulky items like lumber, shingles, drywall. Orbital arm wrappers are standard due to load size/weight and stability needs.

- Manufacturing (General): Securing finished goods (appliances, automotive parts, electronics) for shipment. Turntable wrappers are prevalent.

Industry Adapter Considerations:

- Food/Pharma: Prioritize stainless steel, IP69K washdown ratings, easy-clean designs, and documentation for validation.

- Chemicals/Explosive Atmospheres: Mandatory EX-rated components and motors.

- High-Volume DCs/Manufacturing: Focus on throughput (cycle time), reliability, and integration capabilities (conveyors, WMS/PLC communication). Rotary rings or high-speed turntables.

- Heavy/Unstable Loads (Chemicals, Building Mat.): Orbital arm wrappers are the primary solution.

- Variable Load Sizes: Machines with automatic height sensing and pattern memory are essential.

- Outdoor/Unprotected Areas: Weatherproof enclosures for controls and critical components.

Understanding these core types, principles, parameters, and application nuances forms the foundation for selecting the optimal pallet wrapping solution. The specific demands of the load, environment, and production volume dictate the most suitable machine configuration. Evaluating these factors ensures the chosen wrapper delivers maximum efficiency, security, and return on investment.

2. 卓越之选:如何挑选最佳裹包机 (融入 Best Stretch Wrapping Machine Reviews)

2.1 选购核心考量要素

Selecting the optimal pallet wrapping machine demands careful evaluation against operational realities. Four critical factors determine suitability:

- 负载特性: Define load dimensions (height, width, depth), weight distribution, stability, and surface irregularity. Heavy, unstable, or oversized loads necessitate orbital arm wrappers. Uniform, stable loads suit turntable or rotary ring systems. Fragile items require precise tension control.

- 产量需求: Calculate required pallets wrapped per hour (PPH). Semi-automatic turntable units handle moderate volumes (15-30 PPH). Fully automatic turntables or orbital arms manage 20-50 PPH. High-speed rotary ring systems achieve 60+ PPH for distribution centers.

- 场地限制: Measure available floor space, ceiling height, and conveyor integration points. Turntable wrappers require significant rotation clearance. Orbital arms need ample circumference space. Rotary ring systems demand dedicated linear conveyor paths. Compact “mini” turntable models exist for tight spaces.

- 自动化程度: Assess labor availability and integration needs. Semi-automatic units require operator pallet handling. Fully automatic models integrate with conveyors and automatic pallet dispensers. Robotic integration or PLC communication (e.g., WMS connectivity) elevates automation further.

2.2 深入解读专业评测与用户口碑

Objective analysis of Best Stretch Wrapping Machine Reviews provides invaluable insights beyond specifications. Focus evaluations on these recurring themes:

- Reliability & Uptime: Reviews consistently highlight machines with robust construction (heavy-duty steel frames), quality drive components, and minimal unplanned downtime. Long-term user testimonials reveal true durability under daily stress.

- Film Savings Performance: Machines delivering consistent, high pre-stretch ratios (250%+) while minimizing film breaks directly impact operational costs. Reviews quantify actual film cost reduction versus claims.

- Ease of Use & Changeover: Operator feedback emphasizes intuitive HMIs, simple pattern programming, and rapid film roll changes. Machines requiring minimal training score highly. Complex maintenance procedures receive negative remarks.

- Containment Force: Real-world testing in reviews measures load stability after simulated transport. Consistent, secure wrapping preventing load shift or product damage is paramount.

- Service & Support: User experiences with manufacturer responsiveness, spare parts availability, and technician expertise heavily influence overall satisfaction scores. Local support networks prove critical.

- Safety Features: Effective safety systems (light curtains, emergency stops, guarding) noted in reviews prevent accidents and ensure compliance.

2.3 顶级品牌与热门型号横向对比分析

Leading manufacturers offer distinct strengths across machine types. Key differentiators emerge:

| Feature/Brand | Turntable Focus (High Vol.) | Orbital Arm Focus (Heavy/Odd) | Rotary Ring Focus (Max Speed) |

|---|---|---|---|

| Build Quality | Heavy-gauge steel frames, industrial bearings | Reinforced arm structures, high torque drives | Precision ring alignment, high-speed components |

| Pre-Stretch Tech | Advanced pre-stretch rollers (250-300%), tension control | Robust pre-stretch for heavy film, consistent tension | Ultra-reliable pre-stretch for continuous operation |

| Control System | Programmable PLCs, recipe storage, diagnostics | Simple HMI for varied patterns, load stability focus | High-speed PLCs, conveyor sync, network integration |

| Throughput (Typical) | 20-50 PPH (Auto) | 15-40 PPH | 60-100+ PPH |

| Integration Ease | Conveyor interfaces, pallet dispensers | Forklift-friendly semi-auto setups | Mandatory conveyor integration, upstream/downstream sync |

| Ideal Load Profile | Standard, stable pallets | Heavy (>3000 lbs), unstable, oversized | Uniform, high-volume standard pallets |

2.4 性价比评估与投资回报率 (ROI) 测算

Justifying investment requires concrete ROI analysis. Key cost and savings factors:

- Capital Expenditure: Machine purchase price, installation, and training costs.

- Operational Savings:

- Film Cost Reduction: Pre-stretch technology (250% vs. manual 100%) cuts film usage 50-70%. Calculate:

(Annual Film Cost Manual) x (0.5 to 0.7) = Annual Savings. Example: $50,000 manual film cost x 0.6 = $30,000 saved. - Labor Cost Reduction: Automating manual wrapping eliminates labor. Calculate:

(Operator Hourly Rate + Benefits) x (Hours Saved/Day) x (Operating Days/Year). Example: ($30/hr) x (8 hrs) x (250 days) = $60,000 saved. - Product Damage Reduction: Secure loads reduce claims. Estimate based on historical damage rates.

- Worker’s Comp Reduction: Eliminating manual wrapping reduces strain injuries.

- Film Cost Reduction: Pre-stretch technology (250% vs. manual 100%) cuts film usage 50-70%. Calculate:

- Maintenance Costs: Factor annual preventative maintenance contracts and typical spare parts.

- ROI Calculation:

(Total Annual Savings - Annual Maintenance Cost) / Total Capital Cost = Simple Payback Period (Years). Target payback often < 2-3 years. Example: ($30,000 film + $60,000 labor – $5,000 maint) / $150,000 capex = 0.57 years (~7 months).

Choosing wisely based on load needs, verified performance, and clear ROI ensures the stretch wrapper becomes a strategic asset, not just equipment. Request operational data and demos specific to your loads for the most accurate assessment.

3. 高效持久之道:裹包机维护保养全攻略 (聚焦 How to Maintain a Pallet Wrapping Machine)

3.1 日常操作规范与安全要点

Operational discipline ensures safety and prevents premature wear. Key protocols include:

– Startup Verification: Confirm all safety guards are secured and emergency stop buttons function before initiating machine cycles. Clear the turntable area of debris.

– Load Positioning: Center pallets precisely on turntables to prevent imbalance. Never exceed manufacturer-rated weight capacities.

– Film Handling: Use only recommended stretch film gauges and widths. Ensure film rolls load correctly without cross-threading on pre-stretch rollers.

– Motion Zone Safety: Maintain minimum 1-meter clearance around rotating components during operation. Lockout/tagout procedures apply during any intervention.

– Shutdown Sequence: Follow proper power-down steps after final pallet completion. Clean residual film fragments from rollers and tracks.

3.2 预防性维护计划制定与执行

Structured maintenance intervals prevent catastrophic failures:

| Frequency | Critical Tasks |

|---|---|

| Daily | – Remove film debris from rollers and tracks – Verify safety sensor functionality – Inspect film carriage movement smoothness |

| Weekly | – Check turntable drive chain/belt tension – Lubricate carriage guide rails – Examine pre-stretch roller surfaces for damage |

| Monthly | – Test electrical connections for corrosion – Calibrate film tension sensors – Inspect turntable bearing alignment |

| Annual | – Replace worn gearbox lubricant – Conduct motor performance diagnostics – Validate PLC program integrity |

Maintenance logs documenting each inspection create accountability and trend analysis.

3.3 关键部件深度保养指南

Turntable/Turntable Assembly:

– Degrease drive mechanisms quarterly; apply high-temp lithium grease to bearings

– Measure turntable levelness monthly with precision laser tools

– Inspect drive motor brushes annually; replace if worn below 6mm

Film Carriage System:

– Clean carriage linear guides weekly using non-residue solvents

– Verify vertical lift chain tension bi-weekly (deflection ≤ 3mm)

– Replace worn carriage rollers showing uneven tread patterns

Pre-Stretch Rollers:

– Remove film residue daily with isopropyl alcohol wipes

– Check roller parallelism monthly using feeler gauges

– Replace hardened rubber rollers every 12-18 months

Electrical Components:

– Blow dust from control cabinets quarterly using compressed air

– Test emergency stop circuits monthly

– Inspect cable conduits for abrasion points semi-annually

3.4 常见故障诊断与快速排除技巧

| Symptom | Probable Cause | Immediate Action |

|---|---|---|

| Film breaks | Damaged pre-stretch rollers | Inspect roller surfaces; replace if grooved |

| Uneven wrapping | Incorrect carriage speed setting | Recalibrate film/turntable speed ratio |

| Turntable jitter | Loose drive chain | Adjust tension per manual specifications |

| Carriage stalling | Contaminated linear guides | Clean rails; relubricate with PTFE spray |

| PLC error codes | Loose terminal connections | Power down; reseat all control wiring |

3.5 延长设备寿命的最佳实践与耗材管理建议

- Film Selection: Match film elasticity to pre-stretch ratio capabilities. Avoid incompatible recycled films causing roller slippage.

- Environmental Controls: Maintain ambient temperatures between 10-40°C. Install dust shields in high-particulate environments.

- Component Rotation: Stock critical spares (drive belts, proximity sensors) to minimize downtime.

- Operator Training: Certify staff on proper film loading techniques and basic diagnostics.

- Vibration Monitoring: Install accelerometers on drive motors to detect early bearing failure.

- Lifecycle Tracking: Record cumulative runtime hours for predictive replacement scheduling.

Consistent execution of these protocols reduces ownership costs by up to 40% while extending machine service life beyond 15 years. Maintenance expenditure typically represents less than 3% of total operational savings from automated wrapping.