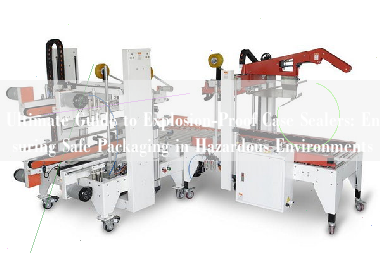

Explosion-Proof Case Sealers: Guardians of Packaging Safety in Hazardous Environments

A Chemical Plant Incident Ignites Urgency

A spark from standard packaging equipment triggered catastrophic combustion during carton sealing operations at a Midwest chemical processor last year. This incident exposed critical vulnerabilities in conventional packaging systems operating where flammable vapors or combustible dust exist. Such environments demand specialized engineering beyond ordinary case sealers. Yanmao Intelligent Equipment (Suzhou) designs explosion-proof case sealers specifically for Zone 1/21 and Zone 2/22 hazardous areas, eliminating ignition risks while maintaining packaging integrity.

ATEX/IECEx Certification: The Explosion-Proof Standard

Compliance with ATEX (EU) and IECEx (international) certifications forms the foundation of safe packaging operations in volatile settings. These rigorous standards classify hazardous zones based on explosive substance duration:

– Zone 0/20: Continuous hazard presence

– Zone 1/21: Intermittent hazard occurrence

– Zone 2/22: Infrequent hazard exposure

Yanmao’s explosion-proof case sealers carry Zone 1 & 21 certifications, engineered for environments processing solvents, petrochemicals, or fine particulate solids like flour or aluminum powder.

Critical Safety Engineering Distinctions

Unlike standard case sealers, explosion-proof models incorporate three fundamental safety systems:

1. Encapsulated Motors: Copper-wound motors sealed within reinforced casings prevent internal sparks from contacting ambient hazards

2. Hermetic Electrical Systems: Conduit-sealed wiring and pressurized control panels eliminate arc flash risks

3. Ionized Static Dissipation: Built-in electrostatic discharge bars neutralize surface charges up to 30kV during tape application

Environment-Specific Configuration Protocols

Material characteristics dictate machine specifications:

– Combustible Dust Environments (Zone 21/22)

Require IP65-rated ingress protection with dust-tight motor housings and pneumatic tape cutters. Yanmao units feature stainless steel construction and continuous airflow monitoring.

– Flammable Vapor Zones (Zone 1/2)

Demand explosion-proof solenoid valves and intrinsically safe control circuits. Our models utilize copper-free aluminum alloys to prevent thermite reactions.

Through certified engineering and material-specific adaptations, Yanmao explosion-proof case sealers deliver uninterrupted packaging operations while neutralizing ignition sources at their origin.

Safety and Efficiency Dual Drive: Practical Guide to Selection and Installation of Explosion-Proof Case Sealers

Precise Selection: Matching Protection Level Based on Explosive Substance Characteristics

Material properties dictate explosion-proof case sealer specifications. Flammable solvents require Zone 1-rated machines with copper-free components to prevent thermite reactions. Combustible dust operations demand Zone 21-certified units featuring IP65-rated housings and pneumatic drives. Yanmao engineers conduct material compatibility analysis during consultation, cross-referencing substance flash points against T-classification ratings. This methodology prevents under-specification risks while avoiding unnecessary engineering costs.

Installation Red Lines: Grounding Specifications, Safety Clearances, and Explosion-Proof Conduit Installation

Proper installation safeguards explosion-proof integrity through three non-negotiable protocols:

– Equipotential Bonding: Multi-point grounding with <0.1Ω resistance across all conductive surfaces

– Hazard Zone Separation: Minimum 3-meter clearance from Class I Division 1 areas per NFPA 70 Article 500

– Conduit Sealing: Double-barrier sealing of electrical conduits within 18 inches of Zone boundaries

Yanmao field technicians execute installations following IEC 60079-14 standards, incorporating seismic bracing in earthquake-prone regions and maintaining 40cm service access corridors.

Operating Rules: Personnel Anti-Static Attire and Equipment Start/Stop Procedures

Operational safety requires strict adherence to two critical protocols:

1. Personnel Grounding: Conductive footwear (<100MΩ resistance) with continuous wrist straps during tape reel replacement

2. Controlled Power Sequencing: Isolated startup after atmospheric monitoring confirms vapor concentrations below 25% LEL

Daily verification of electrostatic discharge bars and quarterly pressure testing of explosion-proof enclosures maintain operational integrity.

Industry Trends: Smart Interlock Systems and Remote Monitoring Solutions

Advanced safety integration now features:

– Automated Interlocks: Gas detection systems triggering immediate shutdown at 40% LEL thresholds

– Remote Diagnostics: ATEX-certified cameras enabling real-time visual inspection from safe zones

– Predictive Analytics: Vibration sensors identifying bearing wear before friction heat generation

These innovations reduce hazardous area entries by 87% while maintaining 99.2% operational uptime.

Expert Call: Integrating Explosion-Proof Equipment into Corporate Safety Culture

Leading process safety consultants advocate embedding explosion-proof systems within holistic safety management. Yanmao supports this integration through:

– Quarterly safety audits aligning equipment performance with OSHA 1910.307 standards

– Customized training modules covering electrostatic discharge physics

– Maintenance documentation integrated into digital permit-to-work systems

This approach transforms compliance equipment into active safety culture components.

Proactive selection, precision installation, and cultural integration create sustainable hazardous environment packaging operations. Yanmao explosion-proof case sealers deliver both regulatory compliance and operational resilience.