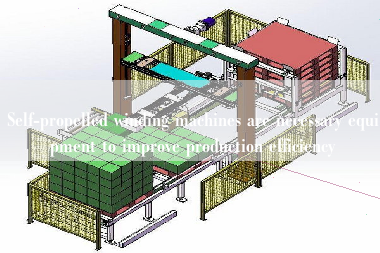

With the rapid development of the modern logistics industry, logistics equipment is becoming more and more diversified and intelligent. As a new type of logistics equipment, self-propelled winding machines are favored by more and more companies for their efficient and intelligent characteristics. This article will introduce in detail the definition, principle, advantages and application of self-propelled winding machine, in order to help readers better understand and apply this equipment and improve production efficiency.

1. Definition of self-propelled winding machine

Self-propelled winding machine is a kind of packaging equipment with autonomous driving function. It can automatically wind, fix, protect and other operations of goods. It adopts electric drive, is equipped with an autonomous navigation system and an intelligent control system, and can carry out automated operations according to different cargo and packaging requirements, thereby improving packaging efficiency and quality.

2. The principle of self-propelled winding machine

The working principle of the self-propelled winding machine mainly includes three parts: autonomous navigation, automatic winding and automatic cutting. First, the autonomous navigation system obtains surrounding environment information through sensors such as lidar and cameras to achieve autonomous navigation and path planning. Secondly, the automatic winding system automatically adjusts the tension and number of layers of the winding film according to the size, weight, shape and other characteristics of the goods to perform the winding operation. Finally, the automatic cutting system automatically cuts the wound film according to the set length and position to complete the winding process.

3. Advantages of self-propelled winding machines

1. Improve packaging efficiency: Self-propelled winding machines can automate winding, fixing, protection and other operations, greatly improving packaging efficiency and quality, and reducing labor and time costs.

2. Improve packaging quality: Automated winding can ensure the consistency of the tension and number of layers of the wrapped film, avoid errors and instability in manual operations, thereby improving packaging quality.

3. Reduce logistics losses: Self-propelled winding machines can tightly wind goods, avoiding friction, collision and loss of goods during transportation, and reducing logistics losses.

4. Improve safety: The self-propelled winding machine adopts electric drive, which avoids safety hazards in manual operation and ensures the safety of operators.

4. Application of self-propelled winding machines

Self-propelled winding machines are widely used in logistics, manufacturing, food processing, medicine and other industries. For example, in the logistics industry, self-propelled winding machines can automate operations such as winding, fixing, and protecting goods, improving logistics efficiency and quality; in the manufacturing industry, self-propelled winding machines can automate product packaging and protection, reducing labor and time costs, and improving packaging quality and production efficiency; In the food processing and pharmaceutical industries, self-propelled winding machines can automate the packaging and protection of products, avoid external pollution and damage to products, and ensure product quality and safety.

In short, as a new type of logistics equipment, self-propelled winding machines are favored by more and more companies for their efficient and intelligent characteristics. By understanding the definition, principles, advantages and applications of self-propelled winding machines, we can better understand and apply this equipment and improve production efficiency and quality.