奶粉装箱机:高效精准的自动化包装解决方案

Precision packaging is paramount in the powdered milk industry. Protecting delicate product integrity while achieving high throughput demands specialized automation. Yanmao Intelligent Equipment (Suzhou) delivers tailored Case Packer solutions engineered specifically for the unique challenges of powdered milk tins, cans, and flexible pouches. These systems ensure gentle handling, precise placement, and consistent output critical for brand reputation and operational efficiency.

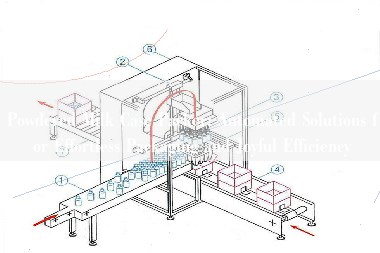

核心功能解析:专为奶粉行业定制的装箱技术

Yanmao Case Packers for powdered milk incorporate distinct features addressing industry-specific needs. Gentle product handling mechanisms prevent damage to delicate containers like metal tins or composite cans. Advanced servo-driven positioning guarantees exact alignment within the shipping case, eliminating shifting during transit that could compromise seals or cause abrasion. Integrated dust management systems are often critical, containing fine powder particles released during the high-speed packing process to maintain a clean production environment and meet stringent hygiene standards common in food and pharma. Versatility in container format handling is key – a single machine often accommodates various tin sizes, can shapes, and pouch types common in infant formula and nutritional powder production lines. High-speed capabilities seamlessly match upstream filling equipment, preventing bottlenecks. Robust construction using food-grade materials ensures durability and simplifies sanitation protocols.

价格因素深度剖析:投资回报率与成本控制

Evaluating a powdered milk Case Packer involves analyzing total cost of ownership and clear ROI. Initial investment encompasses the machine, installation, and integration. Significant savings materialize through dramatic labor cost reduction. Manual case packing is labor-intensive and prone to fatigue-related errors and slower speeds; automation typically replaces multiple operators per shift. Reduced product loss is another financial benefit – precise robotic handling minimizes dropped or damaged containers, directly protecting valuable product and reducing waste. Increased line throughput directly boosts production capacity without expanding labor costs or physical footprint. Enhanced packaging consistency lowers the risk of customer returns due to damaged goods. Operational efficiency gains include minimized line stoppages for manual interventions and reduced costs associated with workplace injuries common in repetitive manual packing tasks. Yanmao systems prioritize energy efficiency and low maintenance requirements, further controlling ongoing operational expenditures.

操作可视化指南:视频教程赋能高效生产

Maximizing the efficiency and uptime of your powdered milk Case Packer demands accessible operational knowledge. Yanmao provides comprehensive video tutorial resources integrated into the support ecosystem. These visual guides cover essential aspects: Routine startup and shutdown procedures ensure safe operation. Step-by-step changeover demonstrations detail adjusting the machine for different container formats (e.g., switching from 900g tins to 400g pouches), minimizing downtime between production runs. Clear visualizations of common troubleshooting steps empower on-site staff to resolve minor issues rapidly without external support calls. Best practices for routine cleaning and maintenance tasks are visually communicated, ensuring hygiene compliance and prolonging equipment life. Basic operational adjustments for optimizing performance with specific powdered milk container types are demonstrated. Accessible video resources directly contribute to faster operator training, reduced human error, increased machine utilization, and sustained peak packaging line performance. Operators gain confidence through visual learning, leading to smoother daily operations.

智能升级与价值延伸:奶粉装箱机的未来竞争力

Packaging efficiency gaps directly impact powdered milk profitability. Leaking containers trigger recalls, inconsistent speeds create bottlenecks, and reactive maintenance fuels downtime. Yanmao Intelligent Equipment (Suzhou) integrates advanced intelligence into Case Packer systems, transforming these vulnerabilities into competitive advantages. Future-ready automation extends beyond mechanical functions, embedding proactive problem-solving and continuous value generation across the packaging lifecycle.

行业痛点破解:解决漏罐、效率低等包装难题

Container integrity failures remain a critical risk for powdered milk brands. Yanmao Case Packers deploy multi-stage inspection protocols. High-speed vision systems scan each tin or pouch pre-entry, rejecting units with damaged seals, dents, or improper closures using real-time image analysis. Force-controlled servo grippers adapt pressure dynamically based on container weight detection, preventing deformation of thin-walled cans during high-speed transfers. Variable speed conveyors synchronize seamlessly with upstream cappers, eliminating accumulation jams that cause spillage. Adaptive robotic path planning compensates for minor container dimension variations, maintaining precise case loading at rates exceeding 120 units/minute. Instantaneous format switching via HMI-preset recipes accommodates batch size changes without line stoppages. These capabilities directly resolve leakage risks and throughput inconsistencies plaguing manual operations.

节能降耗实战:降低奶粉包装综合成本的秘密

Energy and material waste silently erode packaging margins. Yanmao designs incorporate efficiency at the component level. Regenerative servo drives capture braking energy during robotic arm deceleration, repurposing up to 25% of motion power. Smart sleep modes activate during scheduled pauses, cutting idle energy consumption by 60% versus continuous-run systems. Precision case forming mechanisms optimize cardboard usage through right-sized carton selection algorithms, reducing material costs by 8-12%. Compressed air requirements decrease 40% through electric alternatives to pneumatic actuators. Dust containment systems prevent product loss, saving up to 1.2% of material previously lost to environmental contamination. These measurable reductions in energy, material, and product waste compound into significant annual operational savings.

智能运维生态:从操作视频到预测性维护体系

Reactive maintenance models disrupt production. Yanmao establishes a connected intelligence ecosystem. Foundational video resources guide daily operations. Embedded IIoT sensors monitor critical parameters: motor current signatures reveal bearing wear patterns; vibration analysis detects conveyor misalignment; thermal sensors track sealing head performance. Machine learning algorithms process this data, generating predictive maintenance alerts 300-500 operating hours before potential failures. Remote diagnostics portals enable Yanmao engineers to perform virtual inspections, reducing resolution time by 70%. Digital twin simulations test configuration changes offline, eliminating trial-and-error adjustments on live production. Maintenance schedules dynamically optimize based on actual machine utilization data rather than fixed intervals. This transition from corrective to predictive care slashes unplanned downtime by up to 45% while extending equipment service life, creating sustained operational leverage.