What is a High-Level Palletizer?

High-Level Palletizers represent a critical automation solution for modern warehouses and distribution centers. These specialized machines automate the stacking of products, cases, or bags onto pallets at significant heights – typically starting from approximately 4 meters (13 feet) and extending much higher. Their primary function is to build stable, secure unit loads ready for efficient storage in high-bay racking systems or for direct shipment, maximizing vertical space utilization within the facility.

Core Definition

A High-Level Palletizer is an automated material handling system designed to receive individual items, cases, or bags from an upstream conveyor or production line. It precisely positions and stacks these items onto a pallet according to a pre-programmed pattern. The defining characteristic of a high-level system is its ability to build the pallet load at an elevated position, matching the height of high-bay storage racks or enabling direct transfer onto transport vehicles. This eliminates the need for subsequent lifting of the completed pallet load to the required storage height, enhancing safety and efficiency.

Operational Principles

High-Level Palletizers function through a coordinated sequence. Products arrive via an infeed conveyor system. Sensors detect the product’s presence and orientation. The machine’s control system, guided by sophisticated software, directs the stacking mechanism. This mechanism, which could be a gantry-style head, robotic arm, or layer-forming device, picks or pushes the product. It then precisely places it onto a pallet positioned at the elevated build station. The pallet itself is incrementally lowered as each layer is completed. Once the full pallet pattern is achieved, the completed unit load is conveyed out, often directly into high-bay storage or onto a waiting truck or staging area. A new empty pallet is simultaneously fed into the build position, enabling continuous operation with minimal downtime.

Common System Types

Several configurations of High-Level Palletizers exist, each suited to specific applications and product types:

- Column-Based High-Level Palletizers: Feature vertical masts supporting a moving head. The head traverses horizontally (X-axis) along the mast and vertically (Z-axis) up and down the mast. A product handling mechanism (clamp, vacuum head, pusher) on the head performs the stacking. Ideal for handling cases, boxes, and stable bags at high speeds and very high stacking heights.

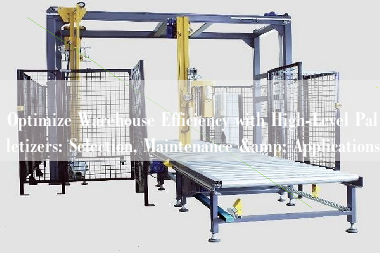

- Gantry-Style High-Level Palletizers: Utilize a bridge-like structure spanning the work area. The stacking head moves along the bridge (X-axis) and along supporting beams (Y-axis), with vertical (Z-axis) movement capability. This design offers a large working envelope, suitable for building large pallet patterns or handling bulky items. Often used for drums, large bags, or mixed SKU pallets.

- Robotic High-Level Palletizers: Employ industrial robots mounted at height. Robots equipped with specialized end-of-arm tooling (EOAT), such as vacuum grippers, clamp attachments, or specialized bag handlers, pick products from a lower infeed conveyor and place them directly onto a pallet positioned at a high-level build station. Offer exceptional flexibility for complex patterns, mixed products, or delicate items. These are specifically termed Robotic Palletizers when utilizing articulated robots.

- Hybrid Systems: Combine elements, such as a layer-forming station feeding a high-level gantry for placing entire layers, optimizing speed for uniform products.

These systems form the backbone of automated high-bay warehousing, transforming loose product flow into optimized unit loads ready for vertical storage or transport.

How to Choose the Best High-Level Palletizer for an Industrial Warehouse?

Selecting the optimal High-Level Palletizer demands careful analysis of operational requirements and technical specifications. Industrial warehouses handling cartons, woven poly bags, drums, or plastic pouches require solutions balancing speed, flexibility, and reliability. The right system eliminates redundant material handling, minimizes labor dependency, and maximizes vertical storage utilization.

Key Selection Criteria

Critical factors determine palletizer suitability:

– Throughput Volume: Assess hourly case/bag/drum handling needs. High-speed operations (>1,000 units/hour) favor robotic or column-based systems.

– Product Variability: Mixed SKUs require robotic flexibility; uniform cartons suit gantry systems.

– Load Specifications: Maximum stacking height must align with racking systems. Drum handling demands specialized end-effectors.

– Integration Complexity: Evaluate upstream/downstream equipment interfaces. WMS compatibility ensures seamless data flow.

– Footprint Constraints: Gantry systems require significant clearance; robotic models offer compact layouts.

– Safety Compliance: ANSI B11.19/ISO 10218 standards are non-negotiable for elevated operations.

Leading Industrial Solutions

Renowned providers offer distinct advantages:

– Robotic Palletizers (FANUC, KUKA): Excel in pattern flexibility for mixed pallets and delicate items like pharmaceutical cartons.

– Gantry-Style Systems (BEUMER Group, Columbia): Ideal for heavy drums (55-gal) and oversized poly bags.

– Column-Based Palletizers (Yanmao Intelligent Equipment (Suzhou)): Deliver high-speed stability for uniform cartons in food distribution.

– Hybrid Configurations (Schneider): Combine layer-forming efficiency with high-level placement for large-scale operations.

Yanmao’s integrated approach incorporates real-time diagnostics and modular designs, enabling future throughput scaling without line redesign.

Performance Optimization Metrics

Quantitative evaluation ensures operational excellence:

1. Cycle Time Analysis: Measure seconds per layer versus theoretical maximum.

2. Uptime Tracking: Target >98% operational availability via predictive maintenance logs.

3. Damage Rate Audits: Record product impacts during transfer – acceptable thresholds under 0.1%.

4. Energy Consumption: Calculate kWh per pallet; servo-driven systems reduce costs 30-40%.

5. Changeover Efficiency: Programmable logic controllers should switch patterns in under 3 minutes.

Simulation software validates throughput before installation. Warehouse managers should conduct material tests using actual product samples, assessing gripper compatibility with woven poly bags, drum surfaces, and coated cartons. Yanmao’s virtual commissioning tools provide 3D line modeling for risk-free scenario testing.

System selection concludes with ROI validation. High-Level Palletizers typically achieve payback in 12-18 months through labor reduction (1-3 operators per shift) and storage density gains exceeding 40%. Request performance guarantees for build quality and throughput compliance during acceptance testing.

Maintaining High-Level Palletizer Systems for Peak Performance

Proactive maintenance preserves palletizer efficiency across carton, drum, and poly bag operations. Yanmao Intelligent Equipment (Suzhou) designs systems with serviceability as a core principle. Consistent upkeep prevents unplanned downtime and extends equipment lifespan, protecting automation investments in warehouses handling 55-gal drums, woven poly bags, and coated cartons.

Daily Maintenance Tasks for System Stability

Operational reliability begins with disciplined routines:

– Structural Inspection: Verify frame integrity and anchor bolts, particularly after heavy drum palletizing cycles.

– Motion Component Lubrication: Apply manufacturer-specified greases to gantry rails and robotic arm joints.

– Gripper Calibration: Test vacuum/pressure levels on bag insertion end-effectors and carton grippers.

– Conveyor Tracking: Confirm belt alignment and tension for carton transfer systems.

– Sensor Validation: Clean photoelectric sensors detecting carton presence and stacking height.

– Debris Removal: Clear packaging fragments from work cells using OSHA-compliant lockout/tagout procedures.

Maintenance logs should document vibration readings and hydraulic pressure levels during peak throughput periods. Yanmao’s remote monitoring portal enables real-time tracking of these metrics.

Diagnosing and Repairing Common Faults

Rapid troubleshooting minimizes production interruptions:

– Layer Misalignment: Check servo motor encoders on column-based systems; recalibrate positioning software.

– Inconsistent Bag Insertion: Inspect suction cups for wear on bag inserting machines; test pneumatic valves.

– Carton Jamming: Examine accumulation conveyor zones for damaged guides or misadjusted sensors.

– Hydraulic Leaks: Trace fluid paths on drum-handling systems; replace O-rings immediately.

– Communication Errors: Verify Ethernet/IP connections between palletizers and upstream case sealers.

Diagnostic tools like Yanmao’s HMI fault trees provide error-specific resolution protocols. Technicians should maintain spare gripper pads, proximity sensors, and filter assemblies for critical components.

Developing an Effective Preventive Maintenance Plan

Comprehensive scheduling aligns with operational demands:

1. Weekly Tasks: Replace air filters in pneumatic systems; inspect gearbox oil levels.

2. Monthly Procedures: Conduct load testing on structural welds; measure chain stretch in carton elevators.

3. Quarterly Activities: Perform laser alignment on robotic palletizers; overhaul drum gripper mechanisms.

4. Annual Review: Replace servo motor brushes; recalibrate safety light curtains and emergency stops.

Maintenance plans incorporate vibration analysis reports and thermal imaging of electrical panels. Yanmao’s modular designs allow component replacement without full system shutdown. Predictive analytics leverage historical performance data to forecast bearing failures or actuator degradation, scheduling interventions during planned line stoppages.

Documentation remains critical. Service records should correlate maintenance activities with key metrics: energy consumption per pallet, mean time between failures, and product damage rates. Yanmao’s technical support teams provide OEM-approved maintenance templates tailored to specific throughput volumes and material types.

High-Level Palletizers in Modern Logistics: Applications and Advantages

High-level palletizers transform warehouse operations by maximizing vertical storage efficiency. These systems stack products at elevated heights, typically exceeding 15 feet, to optimize cubic space utilization. Yanmao Intelligent Equipment (Suzhou) designs palletizing solutions for cartons, woven poly bags, and 55-gal drums, delivering measurable operational improvements across supply chains.

Key Operational Advantages

High-level palletization generates substantial returns:

– Space Optimization: Achieve 300%+ storage density versus floor-level systems by utilizing vertical clearance in distribution centers.

– Labor Reduction: One robotic palletizer replaces 4-6 manual workers handling heavy drum stacking or repetitive carton placement.

– Throughput Enhancement: Process 30+ cartons per minute or 15+ drums hourly with continuous operation cycles.

– Damage Prevention: Precision grippers maintain product integrity during high-stacking of fragile pharmaceuticals or coated cartons.

– Safety Compliance: Eliminate ergonomic risks associated with manual handling of 500+ lb drum pallets.

Warehouses report 18-month ROI through reduced labor costs and minimized product damage claims.

Industry-Specific Implementation Scenarios

High-level palletization excels in high-volume environments:

– Food Processing: Automated stacking of case-sealed cartons in frozen distribution centers, maintaining -20°C environments.

– Chemical Manufacturing: Robotic palletizers handling 55-gal drums with explosion-proof designs for hazardous materials.

– E-commerce Fulfillment: Multi-line integration with case erectors and sealers for mixed-SKU carton stacks.

– Pharmaceutical Distribution: Sterile-compliant systems palletizing poly bag-protected medical supplies.

– Agricultural Bulk Handling: Automated stacking of 50-lb woven poly bags in grain processing facilities.

Implementation data shows 40% faster dock-to-storage cycles in beverage distribution when integrated with upstream packaging systems.

Emerging Technological Developments

Innovation focuses on adaptability and intelligence:

– Vision-Guided Stacking: 3D scanners now identify irregularly shaped cartons or deformed poly bags for optimal placement.

– Predictive Load Optimization: AI algorithms calculate pallet patterns based on real-time shipment data, reducing transportation damage by 22%.

– Modular Scalability: Yanmao’s gantry systems allow height extensions from 18ft to 30ft without structural modifications.

– Energy Recovery Systems: Regenerative drives capture kinetic energy during descent phases, cutting power consumption 35%.

– Mobile Palletizing: Autonomous vehicles with integrated palletizers enabling dynamic warehouse reconfiguration.

ISO-certified engineering ensures compliance with evolving ANSI/RIA R15.08 safety standards for high-reach automation.

Operational data analytics will soon enable self-adjusting pallet patterns based on shipment vibration profiles, further reducing transit damage. Yanmao’s remote diagnostics platform already predicts maintenance needs with 92% accuracy across global installations.