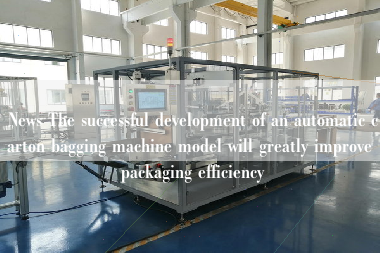

Recently, a new automatic carton bagging machine model has been successfully developed, which will greatly improve packaging efficiency. This automatic bagging machine model adopts an advanced intelligent control system to automatically complete the entire process of bagging cartons, thereby greatly reducing the time and cost of manual operations.

1. Introduction to the functions of the automatic bagging machine model

1. Automatic bagging: Through the intelligent control system, the bagging process of cartons is automatically completed, greatly reducing the time and cost of manual operations.

2. Automatic positioning: The automatic bagging machine model can automatically identify the size and shape of the carton, thereby automatically adjusting the position and angle of the bagging to ensure the accuracy and stability of the bagging.

3. Automatic cutting: The automatic bagging machine model can automatically cut bags, ensuring their appearance and cleanliness.

2. Operation steps of the automatic bagging machine model

1. Place the carton on the workbench of the automatic bagging machine model and start the automatic bagging machine model.

2. The automatic bagging machine model automatically recognizes the size and shape of the carton, and automatically adjusts the position and angle of the bagging.

3. The automatic bagging machine model will automatically complete the bagging process of cartons and automatically cut the bags.

4. After bagging is completed, the automatic bagging machine model will automatically send the carton out.

3. Advantages of automatic bagging machine model

1. Improve packaging efficiency: The automatic bagging machine model can automatically complete the entire process of bagging cartons, greatly reducing the time and cost of manual operations and improving packaging efficiency.

2. Improve packaging quality: The automatic bagging machine model can automatically identify the size and shape of the carton, and automatically adjust the position and angle of bagging to ensure the accuracy and stability of bagging and improve packaging quality.

3. Reduce packaging costs: The automatic bagging machine model can automatically cut bags, thereby ensuring the appearance and cleanliness of the bags and reducing packaging costs.

4. Application scope of automatic bagging machine model

Automatic bagging machine models are widely used in various carton packaging industries, such as food, medicine, electronics, cosmetics and other industries. At the same time, the automatic bagging machine model is also suitable for cartons of various specifications, such as rectangular, square, round and other cartons.

5. Conclusion

The successful development of the automatic bagging machine model will greatly improve packaging efficiency, reduce packaging costs, improve packaging quality, and inject new vitality into the development of the carton packaging industry. It is believed that in the near future, the automatic bagging machine model will become the mainstream equipment in the carton packaging industry.