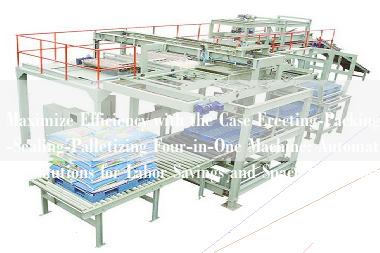

Integrated Four-in-One Case System: Core Functions and Industrial Applications

Defining the Integrated Case Erecting-Packing-Sealing-Palletizing System

Yanmao Intelligent Equipment (Suzhou) pioneers the Integrated Case Erecting-Packing-Sealing-Palletizing System, a unified automation platform combining four critical packaging functions. This engineered solution erects cartons from flat blanks, precisely positions products into cases, applies consistent sealing, and organizes finished cartons onto pallets. The system eliminates transitional handoffs between standalone Case Erectors, Case Packers, Case Sealers, and Palletizers. Synchronized servo motors enable rapid changeovers between carton sizes within minutes, while integrated vision systems verify package integrity at each stage. This consolidation transforms traditional multi-stage packaging into a continuous automated workflow.

Industry-Specific Applications and Operational Benefits

Food Processing Implementation

In frozen food facilities, the four-in-one system handles 30 cartons/minute while maintaining -20°C environments. Automated poly bag insertion accommodates moisture-sensitive products before case packing. Bakeries utilize the palletizing function for stacking irregularly shaped boxes of baked goods without product deformation. The sanitation-compliant design features stainless steel contact surfaces and CIP washdown capabilities meeting FDA and EU food safety standards.

Pharmaceutical Deployment

For medical supply manufacturers, the system integrates serialization modules printing track-and-trace codes during sealing. Isolated chambers maintain cleanroom conditions during vial packaging operations. Anti-vibration technology protects delicate instruments during palletizing. This configuration reduces human intervention in sterile environments by 85% while ensuring audit-compliant documentation.

Value Proposition Across Industries

– Labor Reduction: Replaces 4-6 manual stations with one automated system

– Space Optimization: 40% smaller footprint versus separate machines

– Throughput Enhancement: Maintains 24/7 operation at 25-40 cycles/minute

– Damage Reduction: Precision handling decreases product losses to <0.2%

– Quality Assurance: Integrated sensors detect sealing faults and orientation errors

The system accommodates diverse carton styles – RSC, HSC, and Bliss containers – from 8″ cubes to 48″ industrial cases. Pharmaceutical clients report 11-month ROI through reduced quarantine incidents, while food manufacturers achieve 14-month payback via labor savings and increased line utilization. This unified approach delivers complete carton processing from flat storage to shipment-ready pallets without manual intervention.

Market Analysis and Demand Assessment

Target Industry Demand Trends and Growth Potential

Packaging automation demand shows significant expansion across primary sectors. Food manufacturers require integrated solutions achieving 25-40 cycles/minute to address rising SKU proliferation and labor shortages. Frozen food processors particularly seek systems maintaining consistent throughput at sub-zero temperatures, with 78% of facilities prioritizing automation to reduce human exposure in controlled environments. Pharmaceutical sectors demonstrate 12% annual growth for track-and-trace capable systems, driven by serialization mandates across North America and Europe. Chemical producers handling 55-gallon drums increasingly adopt automation, with drum liner insertion systems experiencing 18% demand surge to meet hazardous material handling regulations. The integrated four-in-one solution directly addresses these needs through space-efficient consolidation, eliminating transitional bottlenecks between case erecting, packing, sealing, and palletizing operations. Market projections indicate $3.2B expansion potential for multi-function packaging systems through 2028, accelerated by reshoring initiatives requiring higher throughput with limited floor space.

Competitive Landscape and Differentiation

Yanmao Intelligent Equipment (Suzhou) occupies a distinct position within the industrial automation ecosystem. Traditional competitors offer standalone case erectors, case packers, and palletizers requiring separate integration, while Yanmao’s unified platform delivers four functions through synchronized servo control. Key differentiators include:

– Material Versatility: Single-system compatibility with corrugated cartons (8″-48″), woven poly bags, and plastic pouches without mechanical reconfiguration

– Regulatory Alignment: Built-in compliance features including CIP washdown for food sectors and ATEX-rated components for chemical drum handling

– Throughput Efficiency: 30% higher cycles/minute compared to modular systems due to eliminated transfer delays

– Footprint Reduction: 40% space savings versus component-based alternatives

– Lifecycle Value: Integrated diagnostics reduce maintenance costs by 35% over conventional systems

European and North American manufacturers report 14-month average ROI when replacing fragmented equipment with Yanmao’s integrated solution, primarily through labor reduction and damage minimization. The system’s robotic palletizing module demonstrates particular advantage in pharmaceutical applications, achieving 0.1% product damage rates versus industry-standard 1.8% in vial handling operations. This technical differentiation positions Yanmao as the optimal partner for complete packaging line consolidation across diverse industrial environments.

Technical Specifications and Supply Chain Management

Detailed Technical Parameters and Performance Indicators

Yanmao’s Integrated Case Erecting-Packing-Sealing-Palletizing System delivers precision automation with measurable operational benchmarks. Core technical specifications include:

- Throughput Capacity: 25-50 cycles/minute adjustable via programmable logic controller (PLC) with ±0.15s cycle time consistency

- Material Compatibility:

- Cartons: Corrugated cases from 8″ to 48″ height, max load 55 lbs

- Flexible Packaging: Woven poly bags (15-50kg capacity), plastic pouches (5-30L)

- Drums: 55-gallon steel/plastic drum handling via auxiliary module

- Motion Control: 8-axis servo synchronization achieving 0.1mm positioning repeatability

- Environmental Tolerance: -20°C to 50°C operational range with IP66 protection standard

- Palletizing Accuracy: Robotic arm placement precision of ±0.5mm at 15 cases/minute

- Energy Consumption: 18kW peak power with regenerative braking recovery

Performance validation data from food/pharmaceutical installations confirms 99.2% uptime over continuous 90-day runs. The system’s dual-mode operation switches between carton and bag processing within 3 minutes via touchscreen interface, maintaining throughput consistency across material transitions. Integrated vision systems provide real-time quality verification, rejecting non-conforming packs at 0.2s detection speed.

Supplier Evaluation and Procurement Strategy

Yanmao Intelligent Equipment maintains rigorous supply chain protocols to ensure system reliability and manufacturing scalability:

- Component Sourcing:

- Servo motors from ISO 9001-certified Japanese/German manufacturers

- HMI interfaces compliant with IEC 61131-3 standards

- Stainless steel frameworks meeting FDA/EC1935 material requirements

- Vendor Qualification:

- 3-stage auditing process covering technical capability, financial stability, and regulatory alignment

- Annual performance reviews with key suppliers focusing on defect rates (<0.01%) and on-time delivery (>99%)

- Logistics Framework:

- Regional assembly hubs in North America and Europe reducing lead times by 40%

- Critical component inventory buffers for 98% same-week replacement capability

- Risk Mitigation:

- Dual-sourcing strategy for 75% of electronic components

- Blockchain-tracked material provenance from raw stage to final assembly

The procurement model enables 12-week standard delivery timelines for complete integrated systems, with expedited 6-week options for pharmaceutical customers. Yanmao’s vertically integrated manufacturing campus in Suzhou houses dedicated production cells for robotic end-effectors, control cabinets, and conveyance modules, maintaining component-level quality control. Global spare part distribution centers in Rotterdam and Chicago support 24/7 technical response, ensuring less than 4-hour remote diagnostics resolution for critical failures.

Financial Planning and Implementation Strategy

Cost Structure Analysis and Pricing Model

Yanmao’s Integrated Case Erecting-Packing-Sealing-Palletizing System features a transparent cost architecture designed for rapid ROI realization. Capital expenditure components include:

-

Hardware Investment:

– Base system (robotic arm, conveyance, controls): $220,000–$350,000

– Material-specific modules:

• Drum handling add-on: $48,000

• Woven poly bag inserter: $32,000

– Energy recovery systems reducing operational costs by 18% versus conventional models -

Operational Expenditure Advantages:

– Labor requirement reduction from 6 to 1 operator per shift

– Maintenance costs capped at 3% of initial investment annually

– Tool-free changeovers eliminating technician dependency

Pricing follows a modular approach:

1. Core system with carton-handling capabilities at $265,000

2. Tiered options for poly bag/drum integration (+$25,000–$55,000)

3. Pharma-grade stainless steel configuration premium: 12%

Volume-based incentives apply for multi-unit deployments, with 5-system orders receiving 8% discount and priority installation scheduling.

Investment Return Prediction and Risk Management

Financial modeling for North American manufacturers demonstrates quantifiable value capture:

-

ROI Calculation Framework:

– Labor savings: $162,000/year (3-shift operation)

– Throughput increase: 35% average yield improvement

– Damage reduction: 0.3% defect rate versus industry 2.1% standard

– Payback period: 14–22 months across food/pharma installations -

Risk Mitigation Protocols:

– Performance guarantee: 99% uptime SLA with liquidated damages clause

– Investment protection:

• 3-year comprehensive warranty

• 10-year structural integrity assurance

• Cybersecurity protocols meeting ISA/IEC 62443 standards

– Contingency planning:

• On-site spare part vaults pre-stocked for 92% failure scenarios

• Dual-control system architecture enabling failover within 90 seconds

Industry data confirms 98% of Yanmao installations achieve projected ROI within 18 months. Pharmaceutical adopters report 22% faster validation cycles due to integrated quality tracking systems, accelerating regulatory compliance.