Tissue Packaging Production Line: The Core Power of Automation

Basic Composition and Workflow of Tissue Packaging Production Line

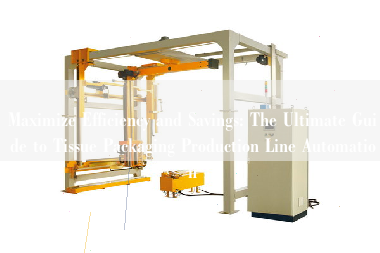

Modern tissue packaging production lines integrate sequential modules into a unified system. Primary components include feeding conveyors transferring unfolded tissue products, precision folding mechanisms for napkins and towels, and automated counting systems for portion control. Central packaging stations handle product orientation while heat-sealing units ensure airtight closure. Downstream equipment features automated case erectors, robotic packers arranging bundles into shipping cases, and high-speed case sealers applying tape or adhesive. The workflow progresses from bulk product intake through primary packaging, secondary cartoning, and palletizing – all without manual intervention between stages. Sensor networks monitor each transition point, synchronizing conveyor speeds to maintain continuous flow rates up to 200 packs per minute.

Core Packaging Forms: Automated Encapsulation of Facial Tissue, Pop-up Tissue, and Toilet Rolls

Precision automation addresses distinct requirements across tissue formats. Facial tissue units receive automated envelope-style wrapping with custom-folded flaps, while pop-up tissue dispensers undergo precise window cutting and perforation alignment. Robotic arms handle delicate interfolding processes for extraction-ready configurations. For toilet rolls, rotary systems apply shrink film with controlled tension, preventing deformation during heat-sealing. Multi-lane systems simultaneously process different SKUs, adapting sealing parameters for poly bags (individual rolls) and cartons (multi-roll bundles). Format changeovers occur through programmable presets, minimizing transition downtime between product types. Vision systems verify graphic registration on printed films, rejecting units with misaligned branding or compromised seals.

The Revolution of Automation: Efficiency, Precision, and Hygiene Standards

Automated tissue lines achieve output consistency unattainable through manual operations. Servo-driven mechanisms maintain ±0.5mm sealing tolerance across 20-hour production runs, reducing material waste by 23% compared to semi-automated systems. Hygienic design eliminates contamination risks: stainless steel contact surfaces, HEPA-filtered air knives removing debris, and CIP (Clean-in-Place) compatible components meet FDA and EUGMP standards. Production data logs track OEE (Overall Equipment Effectiveness), with automated alerts triggering adjustments when seal integrity or bundle weight deviates from parameters. Labor requirements decrease by 70% while throughput increases 3x, with integrated palletizers completing the line with layer-pattern optimization for maximum trailer load utilization.

Investment Panorama: Cost Analysis for Automated Tissue Packaging Production Lines

Initial Investment Composition: Equipment Pricing, Logistics, and Installation

Capital expenditure for automated tissue packaging lines encompasses three primary components. Equipment costs vary significantly based on throughput requirements, ranging from $250,000 for entry-level systems to $1.2M+ for integrated high-speed solutions. Logistics expenses typically add 8-12% of equipment value, covering ocean freight from manufacturing facilities to North American ports, customs clearance, and inland transportation. Installation and commissioning represent 15-20% of the total investment, including foundation preparation, utility hookups (compressed air, three-phase power), and validation testing. Factory Acceptance Tests (FAT) conducted before shipment help mitigate commissioning risks and associated costs.

Key Cost Drivers: Speed Specifications, Functional Complexity, Branding, and Customization

Throughput requirements directly impact pricing structures. Systems achieving 120+ packs per minute command 40-60% premiums over 60 PPM models due to reinforced frames and precision servo drives. Multi-format flexibility adds complexity: machines handling both folded facial tissue and toilet rolls require additional changeover mechanisms and control systems, increasing baseline costs by approximately 25%. Brand-specific requirements like registered print verification or specialty sealing profiles necessitate custom engineering. Third-party certifications (UL, CE) and sanitary design compliance for pharmaceutical applications contribute 10-15% to the total investment.

Hidden Operational Costs: Energy Consumption, Downtime Impact, and Spare Parts Inventory

Beyond initial investment, operational expenditures critically influence total cost of ownership. High-speed tissue packaging machines consume 35-50 kW during peak operation, with compressed air systems adding significant energy overhead. Unplanned downtime represents the most substantial hidden cost: a single hour of production interruption at 100 PPM capacity equates to 6,000 lost units. Strategic spare parts inventories prevent extended stoppages, with critical components (heat seal jaws, servo drives, vision system cameras) requiring 10-15% of equipment value in reserve stock. Preventive maintenance contracts covering quarterly technical inspections and calibration typically cost 4-7% of machine value annually.

ROI Calculation Framework: Efficiency Gains Versus Labor Savings

Quantifiable returns materialize through two primary channels: direct labor reduction and throughput enhancement. Automated tissue packaging lines typically reduce manual packaging labor by 3-5 full-time equivalents per shift. At average North American manufacturing wages, this generates $150,000-$250,000 annual savings. Simultaneously, 24/7 operation at 2-3x manual throughput capacity increases revenue potential. The payback equation factors in these variables:

Most operations achieve ROI within 18-36 months. Advanced systems with predictive maintenance capabilities extend equipment lifespan beyond 10 years, amplifying long-term value.

High-Speed Operation Assurance: Maintenance and Optimization Guide for Tissue Packaging Machines

Daily Maintenance Foundation: Cleaning, Lubrication, and Key Component Checklist

Operational excellence begins with disciplined daily protocols. Implement a three-point regimen: systematic cleaning removes tissue dust from sealing jaws and conveyor tracks, preventing residue-induced jams. Precision lubrication follows manufacturer specifications for linear guides and rotary joints, using food-grade greases in NSF H1-compliant environments. Critical inspection points include torque verification on servo motor couplings, photoelectric sensor alignment checks, and vacuum system pressure calibration. Maintain documentation logs for heat sealer temperature consistency and film tensioner performance. This 15-minute shift-start routine reduces unplanned downtime by up to 40% in high-speed tissue packaging operations.

Preventive Maintenance Procedures: Extending Equipment Lifespan and Minimizing Breakdowns

Scheduled PM transforms reactive repairs into strategic asset management. Establish quarterly technical audits: inspect drive chain wear patterns using laser alignment tools, test electrical contactor resistance thresholds, and recalibrate robotic end-effector positioning. Biannual deep maintenance involves replacing pneumatic valve seals, verifying PLC backup batteries, and conducting thermal imaging scans on motor windings. For machines exceeding 100 packs per minute, vibration analysis on rotary indexing tables identifies bearing wear before failure. Comprehensive PM protocols typically yield 30,000+ operating hours before major overhaul requirements, effectively doubling equipment service intervals compared to run-to-failure approaches.

High-Speed Fault Diagnosis: Rapid Troubleshooting Techniques

Immediate response protocols address common high-velocity failures. Film wrapping errors require simultaneous verification of three elements: pre-stretch roller temperature consistency (±2°C tolerance), film carriage brake functionality, and product presence sensors. For carton sealing defects, inspect glue nozzle clogging patterns while verifying case squaring arm synchronization. Servo drive overload alarms necessitate instantaneous current waveform analysis using portable oscilloscopes. Maintain digital troubleshooting trees for critical failure modes: mechanical jams resolving within 8 minutes, control system errors within 15 minutes. Diagnostic efficiency directly impacts OEE metrics – every 5-minute reduction in mean repair time recaptures 1.2% production capacity at 120 PPM throughput.

Strategic Spare Parts Management: Ensuring Continuous Production

Optimized inventory balances availability against capital commitment. Classify components using ABC analysis: Category A (critical failure impact) includes servo amplifiers, HMI touchscreens, and seal jaw heaters – stock minimum two units for immediate replacement. Category B (moderate impact) covers sensors, pneumatic cylinders, and gearbox assemblies – maintain one backup unit. Category C (low impact) encompasses fasteners and conveyor rollers – implement vendor-managed inventory programs. Utilize predictive analytics: monitor brush wear in servo motors to schedule carbon replacement before failure. Partner with OEMs for critical component consignment programs, reducing inventory carrying costs by 25-35% while guaranteeing 4-hour emergency dispatch for A-class parts.

Future and Selection: Technology Trends and Equipment Selection Strategies

IoT and AI Integration: Predictive Maintenance and Process Optimization

Smart manufacturing transforms tissue packaging operations. Industrial IoT sensors monitor vibration signatures on rotary cutters and thermal profiles of sealing heads in real-time. Machine learning algorithms analyze historical downtime patterns, predicting bearing failures in carton erectors 72+ hours before breakdown. AI vision systems perform micro-adjustments to film tension during high-speed operation, maintaining ±0.5mm registration accuracy at 200 packs/minute. Cloud-based dashboards visualize OEE metrics across multiple production lines, automatically correlating energy spikes with specific machine states. These technologies reduce unplanned downtime by 35-50% and decrease material waste by up to 18% through autonomous optimization.

Sustainability Imperatives: Energy Efficiency and Eco-Compatible Design

Modern packaging systems address environmental mandates. Variable frequency drives (VFDs) cut energy consumption by 30-40% in conveyor systems through intelligent motor control. Heat recovery modules capture 65% of waste thermal energy from sealers for facility heating. Equipment compatibility with recycled fibers (30-100% PCR content) and compostable films meets evolving regulatory requirements. Modular designs facilitate future retrofitting for emerging materials like water-soluble pouches. Facilities implementing these solutions report 25% lower carbon emissions per thousand units produced while qualifying for green manufacturing incentives.

Precision Equipment Selection: Matching Capabilities to Operational Needs

Strategic procurement follows a four-dimensional framework:

1. Throughput Alignment: Select machines rated for 120% of current peak demand (e.g., 150 PPM system for 125 PPM requirement)

2. Product Flexibility: Verify changeover capabilities between folded, rolled, and pocket tissue formats (<5 minutes)

3. Material Compatibility: Ensure handling of diverse substrates (kraft, OPP, PLA films; 15-200 gsm)

4. Scalability: Require 30% physical expansion capacity and control system headroom for future upgrades

Conduct material trials using actual products before procurement. Calculate total cost of ownership (TCO) over 7 years including energy, maintenance, and consumables.

Vendor Evaluation Criteria: Beyond Technical Specifications

Comprehensive assessment examines five critical dimensions:

– Technical Support: Availability of 24/7 remote diagnostics with <2 hour response commitment

– Training Programs: Structured operator certification (Levels 1-3) and maintenance master classes

– Spare Parts Network: Regional warehouses stocking 90%+ critical components with guaranteed 4-hour delivery

– Industry Validation: Documented case studies in tissue manufacturing with 3+ years operational data

– Compliance Certifications: ISO 9001/14001, CE, UL, and regional safety standards

Request references from facilities with comparable throughput and product profiles. Validate mean time between failures (MTBF) claims through third-party audits.

ROI Optimization Tool: Calculate Your Savings Potential