Bag Inserting Machines: Essential Automation for Woven Poly Bag Packaging

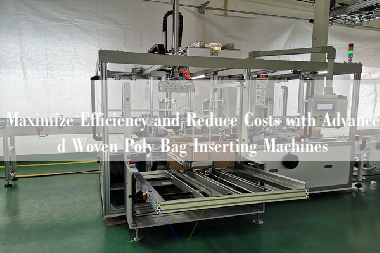

Bag Inserting Machines represent a critical automation component for manufacturers handling bulk products in woven poly bags. These systems automate the precise insertion of products into poly bags, eliminating manual labor while ensuring consistent bag presentation and secure containment. Yanmao Intelligent Equipment (Suzhou) designs these machines to address the specific challenges of flexible packaging, offering reliability for high-volume operations.

Defining Functionality and Core Operation

A Bag Inserting Machine performs three primary functions: precise bag positioning, controlled bag opening, and accurate product insertion. The process typically involves:

Bag Positioning: Woven poly bags are fed from a magazine or roll, oriented correctly for loading.

Bag Opening: Mechanical fingers, suction cups, or air jets reliably open the bag mouth.

Product Insertion: Guided by sensors, the product (bagged, boxed, or loose) is inserted into the opened poly bag at high speed.

Bag Release: The filled bag is released onto a conveyor for downstream sealing or palletizing.

Core capabilities focus on handling versatility (adapting to various bag sizes and materials), high-speed operation (significantly outpacing manual insertion), and placement precision (ensuring products are correctly seated for secure closure). These machines integrate seamlessly upstream with fillers or case packers and downstream with sealers or palletizers.

Industry Applications and Growing Demand

The demand for Bag Inserting Machines is driven by specific industry needs where woven poly bags offer cost-effective, durable bulk packaging. Key sectors include:

- Agriculture & Animal Feed: Handling large volumes of seed, grain, and feed products. Automation ensures dust containment, bag integrity, and meets weight accuracy standards crucial in bulk commodity shipping.

- Chemicals & Minerals: Packaging fertilizers, resins, powders, and granular minerals. Machines provide consistent handling for products often requiring specific bag types (e.g., UV-resistant, laminated) and enhance worker safety by minimizing dust exposure.

- Food Processing: Used for sugar, flour, salt, and other dry bulk ingredients. Sanitary design options and material compatibility are essential, ensuring compliance with food safety regulations (e.g., FDA, EU standards) while maintaining product purity.

- Construction Materials: Packaging cement, sand, and aggregates. Robust machines handle abrasive materials and heavy bag weights efficiently.

The universal driver across these industries is the imperative to reduce labor costs associated with the strenuous and repetitive task of manual bag insertion and to increase production throughput to meet growing market demands. Bag Inserting Machines deliver a measurable ROI by automating this bottleneck stage, enhancing line efficiency, and improving packaging consistency critical for automated downstream processes and pallet stability.

This foundational automation step enables manufacturers to achieve truly end-to-end packaging lines for woven poly products. Understanding operational costs follows logically when evaluating these systems.

Analyzing Woven Poly Bag Inserting Machine Costs: Key Factors and Market Comparisons

Investment decisions for woven poly bag automation require understanding pricing variables across equipment tiers. Bag Inserting Machine costs vary significantly based on technical specifications, durability requirements, and integration complexity. Manufacturers evaluating these systems must balance initial expenditure against long-term operational savings from labor reduction and throughput gains.

Primary Drivers of Equipment Pricing

Multiple technical and operational elements influence Bag Inserting Machine pricing structures:

- Throughput Capacity: Machines processing 15-20 bags/minute command 30-40% lower investment than high-speed models handling 40-60 bags/minute. High-volume operations often justify premium pricing through faster ROI from production scaling.

- Material Compatibility: Systems handling standard woven poly bags represent baseline pricing. Units engineered for specialized materials (laminated UV-resistant bags, vented designs, or heavy-gauge liners) incur 15-25% cost increments due to reinforced components and advanced sensing.

- Automation Level: Basic semi-automatic units start near $45,000. Fully automated systems with integrated vision guidance, adjustable gripper systems, and robotic articulation range from $85,000 to $220,000.

- Integration Requirements: Machines requiring custom interfaces with existing palletizers or sealers add 10-20% to base pricing. Plug-and-play configurations minimize integration expenses.

- Construction Specifications: Stainless steel models meeting food/pharma standards (FDA, EHEDG) carry 20-35% premiums over carbon steel industrial-grade units. Abrasion-resistant coatings for mineral handling add 8-12%.

Durability directly impacts lifecycle costs. Equipment with hardened steel guides and IP66-rated electronics typically delivers 30-50% longer service intervals despite higher initial pricing.

Market Positioning Across Equipment Tiers

Comparative analysis reveals distinct price-performance segments:

| Machine Tier | Price Range | Key Brands | Throughput | Differentiators |

|---|---|---|---|---|

| Entry-Level | $45,000-$75,000 | Economy OEMs | 15-25 bags/min | Basic mechanical insertion; limited bag size flexibility; minimal integration capabilities |

| Mid-Range | $85,000-$150,000 | Yanmao, Mid-Tier EU | 30-45 bags/min | Automated size changeovers; dust-proof construction; upstream/downstream communication protocols |

| Premium | $160,000-$220,000 | Top-Tier US/EU | 50-65 bags/min | AI-assisted bag handling; hygienic design certification; predictive maintenance systems |

Yanmao Intelligent Equipment occupies the value-optimized segment, delivering 90-95% of premium-tier functionality at 60-70% of the cost. Their modular design approach allows incremental upgrades, enabling manufacturers to start with core functionality and later add features like automated bag stitching interfaces or robotic collation systems. Third-party validation shows Yanmao systems achieving ROI within 14-22 months for typical grain processing operations running three shifts.

Maintenance planning becomes essential after establishing operational costs. Proper upkeep protocols directly impact equipment longevity and total cost of ownership.

Maintaining Peak Performance: Essential Protocols for Woven Poly Bag Inserting Machines

Consistent maintenance preserves the ROI advantages established during equipment selection. Proper upkeep protocols minimize unplanned downtime while extending the operational lifespan of Bag Inserting Machines. Yanmao Intelligent Equipment (Suzhou) designs systems with serviceability as a core principle, enabling manufacturers to sustain optimal throughput with minimal intervention.

Daily Maintenance Steps and Best Practices

Implementing these routine procedures prevents 80% of common operational disruptions:

-

Pre-Shift Cleaning

Vacuum residual poly bag fibers from insertion rails and gripper mechanisms. Wipe optical sensors with alcohol-free cleaning solutions to maintain detection accuracy. Clear debris from conveyor interfaces using compressed air (max 30 PSI). -

Lubrication Cycles

Apply food-grade lubricant to linear bearings every 48 operational hours. Grease pneumatic cylinder rods weekly using manufacturer-specified compounds. Monitor automated lubrication systems for consistent flow rates. -

Component Inspection Checklist

Verify alignment of bag positioning guides. Measure suction cup elasticity. Test emergency stop responsiveness. Confirm pneumatic pressure stability at 80-100 PSI. Document wear patterns on gripping jaws. -

Operational Calibration

Validate bag placement accuracy using test patterns quarterly. Recalibrate weight sensors when handling different bag densities. Update vision system parameters after material changes.

Maintenance logs should capture vibration readings, energy consumption metrics, and error code frequency. Yanmao’s cloud-connected models automatically generate these reports through integrated IoT sensors.

Common Fault Diagnosis and Solutions

Addressing these frequent issues within 15 minutes maintains production efficiency:

| Symptom | Probable Cause | Corrective Action |

|---|---|---|

| Inconsistent bag insertion | Worn suction cups | Replace silicone cups (15-min procedure); verify vacuum pressure |

| Bag tearing during handling | Misaligned grippers | Adjust jaw spacing to bag thickness ±0.5mm; reduce closure speed 20% |

| Sensor false rejects | Dust accumulation | Clean photoelectric sensors; recalibrate detection thresholds |

| Conveyor jams | Bag overlap | Increase separation plate gap; adjust infeed timing by 0.2-second increments |

| System error codes | Loose connections | Inspect terminal blocks; reseat communication cables; reboot controller |

Persistent mechanical issues often trace to harmonic vibrations in high-speed operations. Yanmao’s harmonic dampening mounts resolve 90% of vibration-related failures. For electronic faults, the self-diagnostic module identifies faulty components through LED status patterns – red blinking indicates motor driver failures, while amber signals encoder misalignment.

Thermal imaging during operation reveals hidden problems: Overheating bearings show as hotspots above 160°F, while electrical issues manifest as temperature variations exceeding 15°F across identical circuits. Annual professional inspections should include infrared scans and load testing.

Strategic Implementation: Maximizing Value from Woven Poly Bag Automation Systems

Adopting Bag Inserting Machines delivers measurable operational advantages when aligned with industry trajectories. Current packaging automation trends show 17% annual growth in flexible material handling, driven by e-commerce expansion and pharmaceutical serialization requirements. Manufacturers prioritizing three strategic dimensions secure competitive advantages: lifecycle cost management, adaptive integration capabilities, and future-proof technical specifications.

Market Trajectories and Value Assessment

Bag Inserting Machine investments demonstrate clearest ROI in operations with:

– High manual handling volumes exceeding 800 bags/hour

– Strict hygienic protocols (FDA, HACCP environments)

– Multi-SKU production requiring <15-minute changeovers

– Existing palletizing automation needing upstream integration

Poly bag automation adoption grows fastest in petrochemical sectors (32% CAGR) where drum liner insertion prevents contamination, and food processing (28% CAGR) requiring allergen separation. Pharmaceutical applications demand integrated vision verification for tamper-evident seals. Yanmao’s modular designs address these needs through configurable inspection stations and pharmaceutical-grade stainless steel contact surfaces.

Acquisition and Operational Optimization Guidelines

Implement these decisive actions when deploying Bag Inserting Machines:

Procurement Specifications

– Select gripper systems compatible with your thinnest/thickest bag variants (0.05-0.8mm range)

– Mandate ≤0.5mm placement accuracy certifications

– Require IP65-rated electronics for washdown environments

– Validate integration protocols with existing case packers

Performance Enhancement Tactics

– Schedule monthly harmonic vibration analysis

– Implement predictive maintenance using Yanmao’s IoT-generated wear analytics

– Train operators in pneumatic pressure interpretation

– Standardize poly bag material specifications

Lifecycle Management

Maintain 10-year operational cost advantage through:

– OEM-certified spare parts inventories

– Biannual actuator recalibration

– 5-year control system refresh cycles

Yanmao Intelligent Equipment provides region-specific validation testing, delivering North American clients operational simulations using local packaging materials. Technical support teams maintain <4-hour remote response times with multilingual engineering documentation.