1.1 Definition and Core Working Mechanism of Vertical Case Packers

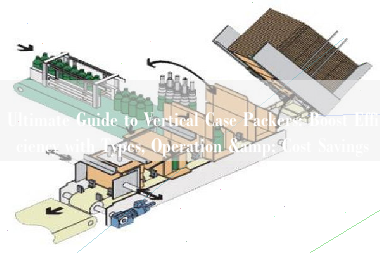

Vertical case packers represent specialized automation systems designed for efficient product loading into erected cartons. These machines function through sequential mechanical processes eliminating manual handling. Primary components include an infeed conveyor receiving products, a carton magazine supplying flat blanks, and precision placement mechanisms.

Operational flow begins with carton blank extraction from the magazine. Vacuum suction cups grip and unfold blanks into rectangular forms. Simultaneously, products advance via conveyor into staging lanes. The critical loading phase occurs through vertical descent mechanisms where grouped products descend directly into open cartons. Gravity-assisted systems position items without surface contact, ideal for delicate packaging. Robotic variants employ articulated arms for complex item orientations.

Processing speeds range 10-60 cartons/minute depending on product dimensions and case complexity. Integrated sensors verify carton integrity before loading while photoelectric counters ensure accurate product counts. Output conveyors transport filled cartons directly to case sealers. This continuous operation cycle achieves 30-50% labor reduction compared to manual lines.

1.2 Main Types and Application Scenarios Analysis

Three dominant vertical case packer configurations address distinct industrial requirements:

Gravity-Feed Systems utilize chute designs for free-fall product loading. This configuration suits rigid packaged goods like canned beverages or boxed pharmaceuticals. Minimal moving parts ensure reliability in high-speed food processing environments. Bottling plants achieve throughputs exceeding 1,200 units/hour with near-zero product damage rates.

Pusher-Type Machines employ horizontal rams to insert products. This mechanical approach handles semi-rigid items such as bagged snacks or pouched chemicals. Adjustable pusher heads accommodate variable product heights from 50mm to 300mm. Cosmetic manufacturers leverage this flexibility for mixed-SKU gift sets requiring precise arrangement.

Robotic Arm Packers deploy 6-axis robots with vision-guided positioning. This advanced solution manages irregular shapes like appliance parts or bundled textiles. Pharmaceutical facilities implement robotic systems for sterile vial packaging where contamination control is critical. Custom EOAT (end-of-arm-tooling) adapts to glassware, plastic tubs, and medical device trays.

Poly bag packaging operations frequently combine vertical case packers with bag inserting machines. This tandem solution automates secondary containment for hygroscopic products like fertilizers or food additives. Drum packaging lines integrate case packers for placing poly-lined boxes into 55-gal containers.

2.1 Operation Manual Details: Procedures, Safety Protocols, and Optimization Techniques

Standard Operating Procedures

Vertical case packer operation follows a defined sequence. Power activation initiates the control system diagnostics. Operators select product-specific profiles through the HMI interface matching carton dimensions and product configurations. Carton blanks load into the magazine with printed side orientation verified. Product infeed conveyors activate receiving items at preset rates.

The automation cycle engages carton erection mechanisms. Vacuum cups extract blanks forming boxes. Optical sensors validate box integrity before loading. Products advance into collation lanes grouping according to programmed counts. Vertical descent mechanisms lower products into cartons. Filled cartons transfer to downstream sealing systems.

Critical Safety Protocols

Safety measures govern all operational phases. Emergency stop buttons position within arm’s reach at each station. Light curtain systems halt machinery upon detecting personnel intrusion. Lockout/tagout procedures implement during maintenance interventions. Operator training mandates avoiding loose clothing near moving parts. Guardrail integrity inspections occur before each shift.

Performance Optimization Methods

Efficiency enhancements focus on parameter adjustments. Product grouping patterns maximize carton space utilization reducing void fill. Conveyor speed synchronization prevents product backlogs. Sensor calibration maintains accuracy during 24-hour runs. HMI data analytics identify recurring jams for mechanical refinement. Automated carton blank replenishment systems minimize operator intervention.

2.2 Daily Maintenance Strategies and Common Troubleshooting Methods

Preventive Maintenance Regimen

Daily maintenance preserves vertical case packer reliability. Lubrication points receive manufacturer-specified greases. Vacuum filters undergo compressed air cleaning. Pneumatic lines inspect for leaks using soap solution tests. Conveyor tracking verifies alignment within 1mm tolerance. Electrical terminals check for corrosion or looseness.

Weekly procedures include photoelectric sensor lens cleaning. Actuator stroke tests confirm full range of motion. Gearbox oil levels monitor against sight glasses. Safety circuit validation tests emergency stop responsiveness.

Fault Diagnosis and Resolution

Common operational disruptions require targeted responses:

- Carton Misfeeds: Inspect suction cup integrity. Verify blank stack alignment. Adjust vacuum pressure settings. Clear magazine debris.

- Product Misalignment: Calibrate lane guide positions. Check encoder synchronization. Examine conveyor belt tension.

- Inconsistent Loading: Validate product count sensors. Adjust descent mechanism timing. Inspect collation lane wear strips.

- Pneumatic System Failures: Monitor pressure gauge readings. Replace worn solenoid valves. Drain moisture from air receivers.

HMI error codes provide specific diagnostic references. Maintenance logs document resolution times identifying chronic issues. Thermal imaging scans detect electrical component stress during peak operation.

3.1 Price Comparison and Cost-Benefit Assessment

Capital Investment Analysis

Vertical case packer pricing varies significantly by configuration. Entry-level single-lane models start near $85,000. High-speed multi-lane systems exceed $250,000. Automation level dictates primary cost differentials. Basic semi-automatic units represent the lowest price point. Fully robotic integration with vision-guided loading commands premium pricing.

Durability impacts long-term value. Stainless steel construction adds 15-25% to base costs but extends service life in food/pharma environments. Modular designs allow scalable investment – facilities may implement core systems initially adding robotic palletizing later.

Operational Cost Reductions

Labor savings deliver measurable ROI. Manual packing stations require 3-6 operators per shift. Vertical case packers operate with one technician monitoring multiple lines. Food processors report 40-60% labor cost reduction after automation. Production consistency improves with automated systems eliminating fatigue-related errors.

Material optimization contributes to savings. Precise carton erecting reduces cardboard waste by 7-12% versus manual forming. Reject rates decline through sensor-based quality control. Energy consumption metrics show modern servo-driven models using 30% less power than older pneumatic systems.

Intangible Value Considerations

Workplace safety improvements lower insurance premiums. Automated handling eliminates repetitive stress injuries from manual packing. Production data collection enables real-time OEE tracking. Faster changeovers accommodate SKU proliferation without adding shifts. Brand protection strengthens through tamper-evident automated sealing.

3.2 Market Dynamics, Barriers, and Evolution

Current Industry Drivers

E-commerce fulfillment demands propel vertical case packer adoption. Third-party logistics providers seek throughput above 30 cases/minute. Pharmaceutical serialization requirements drive intelligent packaging investments. Sustainability pressures increase recycled cardboard usage necessitating adaptive forming systems. Labor shortages make automation economically essential across North America.

Implementation Challenges

Integration complexity remains a primary barrier. Legacy production lines often require conveyor reconfiguration. Space constraints affect 42% of brownfield installations. Technical skills gaps necessitate operator training programs. High-mix manufacturers face programming complexities for diverse carton sizes.

Emerging Technical Advancements

Machine learning algorithms optimize carton blank utilization in real-time. Collaborative robotics enable hybrid manual-automated workcells. IIoT connectivity allows predictive maintenance based on component wear patterns. Universal gripping systems adapt to poly bags and cartons without tooling changeovers. Energy recovery systems capture descent mechanism kinetic energy.

Regional Market Variations

European manufacturers prioritize hygienic design with IP69K-rated components. US food processors demand USDA-compliant lubrication systems. Emerging markets show strongest growth in semi-automated systems. Tariff structures increasingly influence sourcing decisions with localized assembly gaining traction.

Future Development Trajectory

Standardization of MQTT communication protocols will simplify line integration. Nanocoated surfaces may eliminate lubricants in food contact zones. Mobile autonomous packaging units could service multiple production cells. Declining sensor costs will make vision inspection systems ubiquitous by 2028.