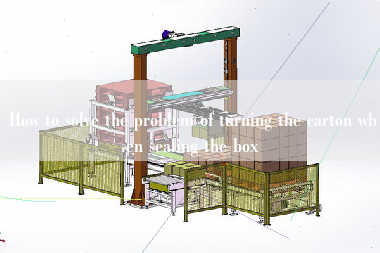

The box sealing machine is one of the indispensable equipment on modern production lines. It can quickly and accurately complete the box sealing task and improve production efficiency. However, when sealing boxes, the problem of turning the carton often occurs, resulting in unstable sealing boxes and affecting product quality. So, how to solve this problem? This article will provide you with several solutions.

1. Check the adjustment of the box sealer

First, it is necessary to check whether the adjustment of the box sealer is correct. If it is not adjusted properly, it will cause the carton to be turned. The specific adjustment methods are as follows:

1. Adjust the height of the box sealer. The height of the sealing machine should match the height of the carton to ensure that the carton does not turn over when sealing.

2. Adjust the width of the box sealer. The width of the sealing machine should match the width of the carton to ensure that the carton will not be turned over when sealing.

3. Adjust the pressure of the box sealer. The pressure of the sealing machine should be moderate. Too large or too small will cause the carton to be turned.

2. Check the quality of the carton

Secondly, it is necessary to check whether the quality of the carton meets the requirements. If the quality of the carton is not good, it will be easy to turn over. The specific inspection methods are as follows:

1. Check the thickness of the carton. The thickness of the carton should meet the requirements, and too thin cartons should be easily turned over.

2. Check the strength of the carton. The strength of the carton should meet the requirements, and a carton that is too weak should be easily turned over.

3. Replace the appropriate tape

Finally, the appropriate tape needs to be replaced. If the tape is not sticky enough, it will cause the carton to be turned. The specific replacement method is as follows:

1. Choose the right tape. The viscosity of the tape should meet the requirements, and the tape that is too weak should be easily turned over.

2. Replace the tape. When it is found that the adhesive tape is not sticky enough, it should be replaced in time.

To sum up, to solve the problem of turning cartons during sealing, we need to start from many aspects such as the adjustment of the sealing machine, the quality of the cartons, and the selection of tape. As long as you pay attention to these problems, you can effectively avoid the flanging of cartons, improve the quality of sealing boxes, and improve production efficiency.