Detailed Technical Specifications of Customizable Palletizers

Core Customization Parameter Specifications

Yanmao Intelligent Equipment (Suzhou) engineers robotic palletizers with precision-customized operational parameters. Production throughput requirements determine cycle speeds ranging from 8-30 cases per minute. Load capacity specifications accommodate payloads from 5kg to 150kg per handling sequence. Travel distance customization spans 3m to 8m horizontal reach with vertical stroke adjustments between 2m and 6m. Footprint optimization allows installations within 10m² to 25m² floor space constraints. Power configurations include 480V/3-phase and 220V/1-phase options with energy recovery systems reducing consumption by 15-30% versus standard models.

Carton Compatibility Technical Indicators

Our robotic palletizers maintain consistent performance across diverse carton specifications. Dimensional adaptability handles cases from 150mm³ mini-boxes to 2000mm oversized containers. Weight tolerance scales from 0.5kg lightweight packaging to 80kg industrial shipments. Material compatibility includes corrugated cardboard, wax-coated boxes, and moisture-resistant variants. Proprietary sensing technology automatically adjusts grip pressure for fragile or irregularly shaped cartons without mechanical reconfiguration. Anti-jam mechanisms prevent misfires with bowed or imperfectly formed cases.

Robotic System Configuration Options

Flexible robotic architectures form the operational core of Yanmao palletizing solutions. Articulated arm configurations offer 4-axis efficiency for standard applications or 6-axis versatility for complex patterns. Reach specifications determine selection between 1400mm compact models and 3200mm extended-reach units. Repeatability precision maintains ±0.5mm positioning accuracy across 100,000+ cycles. Drive systems provide choice between servo-motor precision and hydraulic power for heavy-duty operations. Control interfaces support direct integration with Rockwell, Siemens, and Schneider PLC environments.

End-Effector Customization Solutions

Task-specific end-effectors optimize carton handling across diverse applications. Vacuum cup arrays feature customizable layouts with 4-24 suction points and pressure-sensitive controls preventing product deformation. Mechanical gripper configurations include adjustable claw systems for unstable loads and gentle-grip variants for cosmetic packaging. Hybrid vacuum-clamp units combine technologies for mixed-load palletizing. Quick-change mounting plates enable sub-5-minute tooling swaps between production runs. Specialty options include anti-static systems for electronic components and food-grade certified components.

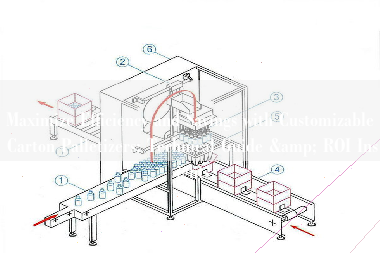

Integrated System and Workflow Design

Infeed Conveyor System Integration Standards

Yanmao’s robotic palletizers feature universal integration interfaces for seamless material handling convergence. Standardized conveyor connections accommodate belt widths from 400mm to 1200mm with adjustable height differentials up to 500mm. Variable-speed synchronization maintains precise case spacing between 200mm and 800mm during transfer operations. Modular accumulation zones buffer up to 15 cartons during downstream interruptions. Divert gate options include pneumatic arms for damaged case rejection and RFID-guided lane switching for SKU-specific routing. All interfaces comply with ANSI/CEMA-402 material handling standards for North American installations.

Intelligent Pallet Pattern Configuration System

Dynamic palletizing algorithms optimize load stability across diverse carton dimensions. Pattern generation software automatically calculates optimal stacking sequences based on real-time carton measurements. Pre-engineered templates support common configurations like brick, pinwheel, and column stacking with custom programmable options. Weight-distribution monitoring prevents top-heavy arrangements through center-of-gravity analysis. The system adapts patterns mid-operation when carton sizes change, eliminating manual reprogramming. Database storage retains over 200 pattern profiles for rapid production changeovers.

Control and Monitoring System Architecture

Centralized HMI platforms provide unified operation management across the packaging line. Industrial PC-based controllers process data from multiple sensor arrays including photoelectric detectors, weight scales, and vision systems. Real-time OEE dashboards display throughput rates, downtime causes, and efficiency metrics. Remote access capabilities enable troubleshooting via secure VPN connections. Predictive maintenance modules track component wear through vibration analysis and cycle counting. Communication protocols include Ethernet/IP, Profinet, and Modbus TCP/IP for cross-platform integration.

Safety Protection Standard Configurations

Multi-layered safety architectures exceed ANSI/RIA R15.06 industrial robot requirements. Perimeter guarding incorporates Type 4 safety light curtains with 14mm resolution detection. Emergency stop circuits feature dual-channel redundancy with Category 3 performance. Access gates install interlocked magnetic switches with time-delay release mechanisms. Pressure-sensitive safety mats surround work envelopes with 7.5kN/mm² detection sensitivity. All safety systems undergo validation testing according to ISO 13849-1 standards before commissioning. Audible alarms and rotating beacons provide visual-auditory warnings during automatic operation.

Economic Analysis and Implementation Plan

Customized Solution Cost Structure

Yanmao’s carton palletizer pricing reflects three primary cost components: modular hardware, engineering customization, and lifecycle services. Base robotic platforms start at $85,000 USD with incremental costs applied for specialized end-effectors ($12,000-$25,000) and advanced vision guidance systems ($18,000-$40,000). Engineering design fees typically represent 15-20% of total project value, covering application-specific modifications like stainless steel construction for food processing or ATEX-certified components for chemical environments. Service packages include 10-year spare part availability guarantees and optional maintenance contracts at 3-5% of equipment value annually. Transparent quotation breakdowns separate mechanical, electrical, and software development costs.

Operational Cost Comparison with Traditional Solutions

Manual palletizing operations require 2-3 workers per shift handling 6-8 cartons/minute, incurring $120,000-$180,000 annual labor expenses. Yanmao’s automated systems achieve 15-25 cartons/minute with 80% reduced labor requirements. Energy consumption analysis shows robotic palletizers operate at 5.2 kW/h versus semi-automatic alternatives averaging 8.7 kW/h. Product damage rates decrease from 1.2% to 0.3% through precision handling, reducing product loss costs by $15,000 annually for medium-volume operations. Maintenance expenses prove 40% lower than conveyor-based systems due to reduced wear components.

Investment Return (ROI) Calculation Model

ROI projections utilize the formula: [(Annual Savings – Annual Costs) / Initial Investment] x 100. Key variables include labor reduction (calculate at $25/hour per operator), throughput increase (value additional units palletized), and damage reduction (product value x 0.9% savings). A typical installation handling 200 cartons/hour shows 24-month payback:

– Initial investment: $150,000

– Annual savings: $92,500 ($78,000 labor + $9,500 damage reduction + $5,000 energy)

– Annual costs: $7,500 maintenance

– Annual net gain: $85,000

Yanmao provides interactive ROI calculators incorporating local wage rates and production volumes.

Installation, Commissioning, and Maintenance Specifications

Implementation follows a four-phase protocol:

1. Site Preparation (5-10 days): Floor load verification (≥ 5,000 kg/m²), power supply stabilization (480V ±10%), compressed air provision (6 bar, 200 L/min)

2. Mechanical Installation (3-5 days): Foundation bolting (M24 anchor bolts), conveyor alignment (±0.5mm tolerance), safety perimeter setup

3. System Commissioning (7-14 days): Pattern validation tests, speed ramping protocols, safety circuit certification

4. Operator Training (3 days): HMI operation, emergency procedures, basic troubleshooting

Preventive maintenance requires quarterly inspections: harmonic drive lubrication (ISO VG 320), belt tension verification (±5% spec), and vision calibration. Remote diagnostics via YanmaoConnect® portal enable real-time performance monitoring with automated spare part ordering.