Steel strip winding technology is a packaging technology widely used in modern industry. It can wind steel strip, aluminum strip, copper strip and other materials together to form a tight package to protect the safety of goods. Steel strip winding machine is an automated packaging equipment that can effectively improve production efficiency and reduce labor costs. This article will introduce steel strip winding techniques from the following aspects to help readers master this technology and improve production efficiency.

1. Basic principles of steel strip winding technology

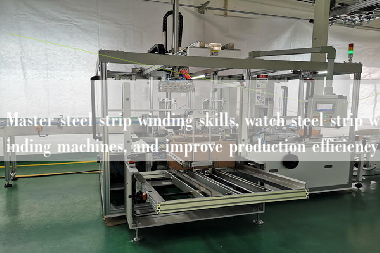

Steel strip winding technology is a packaging technology that winds steel strips around goods. It can effectively protect the goods and prevent them from being damaged during transportation. The working principle of the steel strip winding machine is to pull the steel strip out of the reel, pass through the tension adjuster and guide roller, and then wind it around the cargo. After the winding is completed, the steel strip will be automatically cut to complete the packaging.

2. Operating steps of steel strip winding technology

1. Goods preparation: Before winding the steel strip, the goods need to be prepared. Goods should be placed on a level ground for easy entanglement.

2. Adjust the winding machine: Place the winding machine at an appropriate position away from the cargo. Then, adjust the height and angle of the winding machine to facilitate winding.

3. Place the steel strip: Pull the steel strip from the reel and place it between the tension regulator and the guide roll of the winding machine.

4. Start winding: Press the start button of the winding machine to start winding. The winding machine will automatically wind the steel strip around the cargo until the winding is completed.

5. Cut the steel strip: After winding is completed, the steel strip will be automatically cut. If you need to cut the steel strip manually, you can use a cutter to cut it.

6. Completing packaging: After the winding is completed, move the goods away to complete the packaging.

3. Precautions for steel strip winding technology

1. Adjust the height and angle of the winding machine to facilitate winding.

2. Adjust the tension regulator of winding machine to ensure proper tension of steel belt.

3. Pay attention to the position of the steel strip during winding, and do not let the steel strip loose or too tight.

4. In the winding process, pay attention to safety and avoid accidents.

5. During the winding process, attention should be paid to saving steel strips and avoiding waste.

4. Watch the video of the steel strip winding machine to improve production efficiency

Watching videos of steel strip winding machines is an effective way to improve production efficiency. By watching the video, you can understand the operating steps and precautions of the steel strip winding machine, so as to better master the steel strip winding skills. In addition, watching videos can also help workers familiarize themselves with the operation of steel strip winding machines, improve operating efficiency, and reduce labor costs.

In short, mastering steel strip winding skills and improving production efficiency is a very important technology in modern industry. By understanding the basic principles, operating steps and precautions of steel strip winding technology, as well as watching videos of steel strip winding machines, you can better master this technology, improve production efficiency and reduce costs.