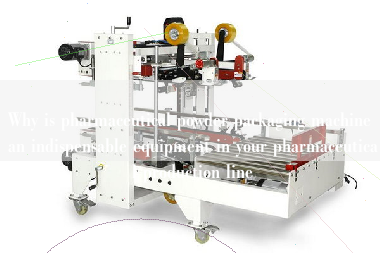

As people’s awareness of health increases, the demand for drugs in the market continues to increase. For drug manufacturers, how to ensure the quality and safety of drugs is very important. As an indispensable equipment in the pharmaceutical production line, the importance of the pharmaceutical powder packaging machine is self-evident. This article will give you a detailed introduction to the operating steps of the pharmaceutical powder packaging machine and its importance in the pharmaceutical production line.

1. Operating steps of the pharmaceutical powder packaging machine

1. preparations

Before using the pharmaceutical powder packaging machine, the machine needs to be inspected and cleaned to ensure that the machine is in normal condition. At the same time, it is also necessary to prepare the required drug powder and packaging bags.

2. Adjust packaging machine parameters

Adjust the parameters of the drug powder packaging machine according to the nature of the drug powder and the size of the packaging bag. It mainly includes parameters such as the size, filling volume, and sealing temperature of the packaging bag.

3. began wrapping

Put the prepared drug powder into the hopper of the drug powder packaging machine, start the machine, and start automatic packaging. During the packaging process, the quality and sealing of the packaging bag need to be constantly checked to ensure the integrity of the packaging bag and the quality of the drug powder.

4. cleaning work

After packaging, the pharmaceutical powder packaging machine needs to be cleaned and maintained to ensure normal use of the machine.

2. The importance of drug powder packaging machines in the drug production line

1. improve production efficiency

The pharmaceutical powder packaging machine can automatically complete the packaging of pharmaceutical powder, greatly improving production efficiency. At the same time, due to its high speed and high precision characteristics, it can ensure accurate filling and sealing of pharmaceutical powder, improving the stability and efficiency of the production line.

2. ensure drug quality

The drug powder packaging machine can adjust packaging parameters according to the nature of the drug powder and the size of the packaging bag to ensure the filling volume and sealing quality of the drug powder. At the same time, due to its high degree of automation, it can reduce the impact of human operations on drug quality and ensure the quality and safety of drugs.

3. reduce production costs

The pharmaceutical powder packaging machine has a high degree of automation, which can reduce manual operations and reduce production costs. At the same time, due to its high efficiency and high precision characteristics, it can reduce the waste of pharmaceutical powder and reduce production costs.

4. enhance corporate image

Drugs are products related to people’s health and have very high requirements for the quality and safety of drugs. Pharmaceutical powder packaging machines can ensure the quality and safety of medicines, enhance corporate image, and enhance consumer trust and recognition.

To sum up, pharmaceutical powder packaging machines are indispensable equipment in the pharmaceutical production line. Its characteristics of high automation, high efficiency, high precision and ensuring drug quality can improve production efficiency, reduce production costs, and enhance corporate image. It is one of the necessary equipment for drug production companies.