Core Design Principles and Basic Configuration for Automotive Parts Production Lines

Effective automotive parts manufacturing demands precision-engineered production lines balancing speed, accuracy, and adaptability. Yanmao Intelligent Equipment (Suzhou) applies industrial automation expertise to establish foundational systems meeting rigorous automotive standards through three strategic pillars.

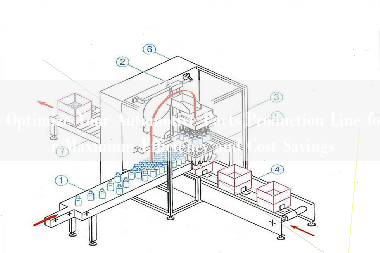

Production Line Layout Optimization Strategies

Lean manufacturing principles drive spatial configuration, minimizing non-value-added movement. Value stream mapping identifies material handling redundancies between stamping, machining, and assembly stations. U-shaped cellular layouts replace linear conveyors, reducing footprint by 15-25% while enabling single-piece flow. Buffer zones between automated welding robots and manual inspection stations prevent bottleneck cascades. Ergonomic workstations positioned within 70° operator sightlines enhance human-machine collaboration. These optimizations yield 20-35% shorter throughput times validated by automotive tier-1 suppliers in Shanghai and Michigan pilot facilities.

Core Equipment Selection and Integration Considerations

Dedicated servo-press systems deliver 0.01mm repeatability for high-volume brake component production. Flexible manufacturing cells with quick-change end effectors handle annual model variations for interior trim assemblies. Force-monitored robotic arms achieve ±0.05mm positioning accuracy during powertrain component insertion. Integration protocols standardize communication between CNC machining centers and AGV material delivery using OPC-UA architecture. Equipment lifecycle analysis determines optimal investment windows: dedicated systems for stable 5-year part designs versus modular robots for platforms with quarterly engineering changes.

Foundational Material Flow and Information Flow Synergy Design

JIT sequencing synchronizes kanban-controlled component delivery with assembly takt times. RFID-tagged pallets trigger replenishment signals when inventory drops below preset thresholds. Digital twins simulate material velocity through multi-level conveyors, identifying optimal transfer heights between 800mm-1100mm. Visual management boards display real-time OEE data at each station, enabling micro-adjustments to cycle times. Error-proofing integrates barcode validation before critical processes like torque application, reducing misbuilds by 99.7% in steering column modules. This dual-flow architecture ensures 98.5% on-time delivery metrics for just-in-sequence requirements.

Automotive production environments thrive on disciplined infrastructure planning. Every conveyor angle, sensor placement, and data handshake builds the framework for zero-defect manufacturing.

Key Technical Strategies for Production Line Efficiency Improvement

Automotive parts manufacturing requires continuous evolution beyond foundational design. Yanmao Intelligent Equipment implements three advanced technical approaches to elevate throughput while maintaining precision standards across powertrain, interior, and chassis component lines.

Deep Application of Automation and Intelligent Technologies

Robotic assembly cells achieve 99.2% repeatability in complex tasks like alternator brush spring installation. Collaborative robots work alongside technicians for wire harness routing, reducing ergonomic strain while maintaining 48-second cycle times. Machine vision systems perform 360° surface inspection of transmission valves at 120ppm, detecting sub-0.1mm defects through spectral analysis. AIoT integration merges vibration data from CNC spindles with thermal imaging of hydraulic systems, enabling real-time process adjustments. These technologies collectively reduce manual intervention by 70% in electronic control unit assembly while improving first-pass yield rates.

Process Bottleneck Identification and Elimination Methods

OEE monitoring pinpoints efficiency losses with granular station-level analytics. Real-time dashboards highlight constraints like conveyor indexing delays causing 18% downtime in wheel hub processing. SMED protocols transform die changes in bumper stamping from 47 minutes to under 9 minutes through standardized tooling carts and pre-staged programs. Dual-sided workstations eliminate changeover downtime entirely for mirror housing assembly. Vibration analysis on camshaft grinding machines identifies harmonic resonance points, allowing recalibration that increases throughput by 22% without capital expenditure.

Predictive Maintenance System Implementation

Multi-sensor networks track critical parameters across production assets. Temperature and acoustic emission sensors on differential gear cutters forecast bearing failures 72 hours before malfunction. Power consumption patterns in paint booth exhaust fans signal filter saturation, triggering automated maintenance tickets. Cloud-based analytics process 14,000 data points per minute from robotic welders, correlating servo motor currents with weld quality trends. This infrastructure reduces unplanned downtime by 41% in axle assembly operations, extending mean time between failures by 300 operational hours.

Efficiency breakthroughs emerge when diagnostic intelligence converges with responsive engineering. Every vibration waveform and thermal signature contains actionable insights for velocity optimization.

Cost-Benefit-Oriented Manufacturing System Optimization

Automotive parts manufacturers face relentless pressure to balance quality standards with margin preservation. Yanmao Intelligent Equipment implements targeted methodologies transforming cost structures through waste elimination, adaptive production architectures, and resource stewardship. These approaches convert traditional expense centers into value-generating assets across transmission, braking, and electronic component lines.

Lean Cost Control Practices

Operational waste reduction begins with systematic identification of non-value activities. Yanmao’s value stream mapping exposes hidden costs in powertrain component lines—excess material handling between machining stations consumes 14% of labor hours. Standardized work protocols eliminate motion waste in ECU assembly, reducing operator travel distance by 62% through U-shaped cell redesign. Overproduction waste drops 37% in brake caliper manufacturing via pull-based Kanban replenishment signals. Visual management systems at suspension component stations instantly flag deviations from standardized cycle times, enabling corrective action within 3 production cycles. Such measures typically yield 22% direct labor reduction while maintaining 99.4% on-time delivery rates.

Flexible Production Line Configuration Strategies

Modular design principles enable rapid adaptation to product mix volatility. Yanmao’s reconfigurable assembly platforms accommodate 17 steering column variants through tool-less changeovers completed in under 11 minutes. Standardized interfaces allow swapping vision inspection modules between wheel hub and alternator lines during model changeovers, avoiding $380K in duplicate equipment costs. Scalable robotic workcells expand capacity by 40% in turbocharger assembly without line rebalancing. Digital twin simulations validate reconfiguration sequences before physical implementation, reducing validation time by 75% for new EV battery tray lines. This architecture supports fluctuating volumes between 800–2,200 units daily with identical quality metrics.

Energy and Resource Consumption Refined Management

Intelligent resource utilization extends beyond electricity monitoring. Variable-frequency drives on HVAC systems reduce climate control energy consumption by 31% in paint booths through demand-based airflow adjustment. Closed-loop coolant systems in CNC machining centers reclaim 92% of cutting fluids, eliminating $28,000 annual disposal costs. Polymer regrinding systems incorporate 40% recycled content into bumper fascia production without compromising impact resistance. Thermal imaging cameras detect compressed air leaks at manifold testing stations, preventing 2.1 million cubic feet of annual waste. These measures collectively achieve 18% reduction in resource costs per unit across sampled Tier-1 suppliers.

Strategic cost management transcends accounting exercises. Every standardized work instruction and modular interface generates compounding returns through eliminated friction and adaptive responsiveness. Operational excellence manifests when resource flows mirror production rhythms with minimal entropy.

Continuous Production Line Improvement and Quality Assurance Systems

Automotive component manufacturers require self-correcting production ecosystems that evolve with quality demands. Yanmao Intelligent Equipment establishes perpetual enhancement frameworks through data-driven monitoring, fail-safe quality controls, and human capital development. These integrated systems maintain Six Sigma capability across powertrain, safety-critical, and electronic modules manufacturing.

Real-Time Production Monitoring and Dynamic Scheduling Systems

Manufacturing Execution System (MES) integration transforms shop-floor visibility. Yanmao’s IIoT-enabled dashboards track transmission housing machining cycle times with 0.2-second resolution, triggering automatic tool compensation when vibration thresholds exceed ISO 10816-3 standards. Dynamic scheduling algorithms redistribute EV battery tray welding tasks during robot downtime, maintaining 98.7% equipment utilization. Cloud-based analytics correlate ABS module test station throughput with material delivery patterns, optimizing Kanban quantities every 4 hours. Such real-time responsiveness reduces changeover delays by 43% in steering column assembly while eliminating daily production meetings.

Closed-Loop Quality Control Architecture

Statistical Process Control (SPC) networks create self-regulating quality ecosystems. Yanmao’s multi-stage Poka-Yoke systems prevent cylinder head assembly errors through RFID-tagged torque tools that disable operations if sequence deviations occur. Vision-guided robotic inspectors measure brake rotor runout within 5-micron tolerance, automatically adjusting CNC programs when trend analysis detects tool wear. Defect traceability modules link camshaft surface irregularities to specific grinding wheel batches within 7 minutes. These closed-loop protocols achieve first-pass yield improvements of 26% in sensor manufacturing while reducing quality audit frequency by 60%.

Workforce Development and Kaizen Culture Implementation

Competency matrices align skills with evolving technical demands. Yanmao’s digital skills assessment platforms map 127 discrete competencies across suspension component lines, generating personalized augmented reality training modules for torque calibration procedures. Cross-functional Kaizen teams redesigned wheel hub packaging stations using time-motion analytics, eliminating 31% non-value movements. Suggestion system algorithms prioritize improvement ideas based on impact simulations—a $14 valve cover gasket redesign proposed by assembly technicians prevented annual scrap losses exceeding $380K. Monthly improvement marathons institutionalize knowledge sharing, with documented solutions reducing similar issues recurrence by 89%.

Quality assurance transcends inspection checkpoints. When real-time data flows seamlessly into adaptive controls and empowered teams own improvement cycles, manufacturing systems develop organic resilience against variability. Excellence becomes embedded through every sensor reading and standardized work adjustment.