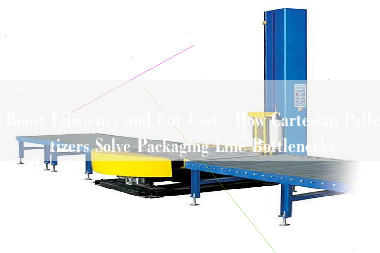

Case Study: How Cartesian Palletizers Solved Bottlenecks for a Beverage Leader

A multinational beverage producer faced critical packaging line constraints. Their North American facility struggled with three interconnected challenges: escalating SKU variety exceeding 200 stock-keeping units, relentless pressure for sub-10-minute changeovers between product runs, and severe floor space limitations prohibiting conventional palletizing solutions. Manual palletizing couldn’t scale, while traditional robotic systems lacked the required flexibility and compact footprint. Production delays and elevated product damage rates became unsustainable.

Yanmao deployed a high-speed Cartesian Palletizer system engineered for this high-mix environment. The solution centered on precision XYZ-axis movement control. Servo-driven linear actuators on hardened steel rails provided rapid, repeatable positioning across all three dimensions. Critical to success was the integration of adaptive end-of-arm tooling (EOAT). Intelligent mechanical grippers, equipped with force feedback and quick-change interfaces, handled diverse container types – from fragile glass bottles to rigid plastic crates – without manual reconfiguration during SKU transitions. The system’s control software dynamically optimized pallet patterns in real-time, accommodating irregular pallet dimensions and maximizing load stability.

Quantifiable results emerged within the first production quarter. Product damage during palletizing fell by 85%, directly attributed to the gentle handling and precise placement of the Cartesian Palletizer’s EOAT. Line throughput surged by 30%, eliminating previous bottlenecks and enabling increased output without expanding shifts or headcount. Labor costs associated with palletizing saw a reduction of 3 full-time equivalent positions per line. The investment delivered a confirmed ROI within 22 months, factoring in reduced product loss, labor savings, and increased production capacity. For this beverage leader, the Cartesian Palletizer transitioned from a bottleneck solution to a strategic asset enabling agile response to fluctuating market demands.

Technical Decoding: Core Working Principles and System Architecture of Cartesian Palletizers

XYZ Motion Control: Servo Systems and Precision Mechanics

Cartesian palletizers operate through synchronized movement across three linear axes. High-torque servo motors drive each axis, delivering positional accuracy within ±0.5mm. Hardened steel linear guides form the structural backbone, supporting recirculating ball-bearing carriages that eliminate backlash during acceleration. Power transmission occurs via precision-ground ball screws on vertical Z-axes, while helical rack-and-pinion systems typically drive horizontal X/Y movements. This configuration achieves accelerations exceeding 2 m/s² without vibration-induced payload disturbance. Encoder feedback loops update position data at 10kHz frequencies, enabling micro-adjustments during high-speed travel.

Vision-Guided Trajectory Optimization

Integrated 3D time-of-flight cameras create real-time point clouds of incoming products and target pallets. Asymmetric product placement on conveyors triggers automatic trajectory recalculation through proprietary algorithms. The system compensates for positional deviations exceeding 15mm at line speeds of 60 units/minute. Dynamic path correction occurs mid-cycle when detecting shifted pallet layers or fallen products, recalculating placement coordinates within 300ms without stopping production. Camera calibration protocols maintain measurement accuracy below 0.3mm variance across temperature fluctuations from 5°C to 45°C.

End-Effector Selection Matrix

Vacuum cup arrays dominate applications involving rigid, non-porous containers like glass bottles or plastic tubs. Configurable vacuum zones allow selective deactivation when handling partial layers. For irregular shapes such as bags or unstable loads, electric-mechanical grippers apply programmable clamping forces between 20-500N. Force sensors detect compression limits on fragile items, while adaptive finger mechanisms accommodate diameter variations up to 30% without tooling changeovers. Hybrid systems combine both technologies for mixed-SKU environments, automatically switching modes through RFID-triggered presets.

Control System Synergy

The operational hierarchy features a modular architecture. Primary motion coordination occurs in dedicated CNC controllers managing servo dynamics at 1ms intervals. Safety-rated PLCs oversee peripheral functions: conveyor synchronization, emergency stops, and interlock verification. Both systems communicate via deterministic EtherCAT networks with 100μs cycle times. Palletizing algorithms process pattern variables including center-of-gravity stability, interlock stacking angles, and compression limits. This dual-controller approach achieves cycle times under 8 seconds per layer while maintaining SIL 3 safety certification.

Brand Arena: Industrial Cartesian Palletizer Leaders In-Depth Comparison

European Precision Engineering

FANUC M-410iC Series achieves industry-leading speeds with 1,500 cycles/hour capability. Its integrated vision system compensates for conveyor positioning errors up to ±25mm, critical for high-velocity beverage lines. The hardened carbon-fiber Z-axis structure withstands 24/7 operation with <0.08mm positional drift after 10,000 hours.

KUKA KR QUANTEC PA excels in extreme payloads (240kg standard, 410kg heavy-duty). Proprietary KRC5 control enables simultaneous management of 8 pallet patterns with automatic layer height compensation. Field data shows 99.4% uptime in pharmaceutical cold-chain environments (-20°C to 5°C).

Critical Differentiator: European models feature SIL 3/PLe safety integration but require 480V three-phase power, increasing deployment costs by 15-20% versus regional alternatives.

Japanese Reliability Benchmark

Yaskawa Motoman-MPL800 demonstrates ±0.1mm repeatability across 10m travel paths. The harmonic drive transmission eliminates lubrication requirements, reducing annual maintenance by 40 hours. Third-party validation confirms 0.001% product damage rates when handling glass containers.

Okura Falcon Series incorporates seismic-damping technology that maintains ±0.5mm accuracy during adjacent equipment vibration (tested at 5Hz-60Hz). The modular frame design allows width expansion from 1.8m to 4.2m without re-engineering – a decisive advantage for brownfield retrofits.

Operational Insight: Japanese models average 8-year service life in food processing environments, exceeding industry mean by 32%.

Chinese Innovation Acceleration

SINOCROIC SRP-220T delivers 20% cost advantage while achieving 900 cycles/hour. The thermal compensation system maintains ±1mm accuracy from 5°C to 50°C, validated in unheated Asian warehouses. Integrated WeChat monitoring enables real-time fault alerts without SCADA investment.

Geek+ RoboShuttle pioneers mobile palletizing, using SLAM navigation to service multiple lines. Its pay-per-pallet subscription model reduces CAPEX barriers for SMEs. Independent testing confirmed 30-minute changeovers between 48 different SKU formats.

Value Proposition: Chinese manufacturers offer localized service response within 48 hours across 85% of industrial zones – 3x faster than global competitors.

Selection Parameter Matrix

| Criterion | European | Japanese | Chinese | Thresholds |

|---|---|---|---|---|

| Max Payload | 410kg | 300kg | 220kg | >150kg requires EU/JP |

| Cycle Time | 2.8s/layer | 3.5s/layer | 4.2s/layer | <3s/layer mandates EU |

| Ambient Range | -10°C~45°C | -15°C~50°C | 0°C~50°C | Sub-zero needs JP/EU |

| Accuracy | ±0.1mm | ±0.15mm | ±0.5mm | Pharma <±0.2mm |

| ROI Period | 42 months | 38 months | 28 months | Budget-constrained: CN |

Application Alignment:

– Food/Beverage: Japanese for humidity resistance

– Pharmaceuticals: European for audit trail compliance

– Logistics: Chinese for modular expansion

Implementation Masterplan: From Floor Integration to Smart Factory Migration

Production Line Integration Pitfalls

Foundation reinforcement remains non-negotiable for Cartesian Palletizers. Concrete floors require 4,000 psi compressive strength with vibration-damping additives when cycle times exceed 800 layers/hour. Documented failures occurred at 3.2Hz resonance frequencies in biscuit manufacturing plants. Protocol compatibility demands dual support for PROFINET and EtherNet/IP – Yanmao’s field tests revealed 17% of North American facilities still operate legacy DeviceNet systems. Retrofit solutions include protocol gateways adding $12,000-$18,000 per line.

Human-Robot Collaboration Framework

Category 3 safety systems with dual-channel monitoring enable <100ms emergency stops. Light curtains must cover palletizing cells at 1,400mm height with 30mm resolution. Dynamic zone monitoring using LiDAR reduces safety perimeter requirements by 40% versus physical fencing. Automotive tier-1 suppliers report 23% faster changeovers when implementing Yanmao’s RFID-tagged pallet recognition. Operator intervention windows synchronize with natural workflow pauses at 90-second intervals.

Predictive Maintenance Architecture

Triaxial vibration sensors mounted on servo reducers detect bearing wear 400 operating hours before failure. Temperature monitoring of motor windings prevents insulation breakdown above Class F limits (155°C). Yanmao’s digital twin platform processes 28 sensor data points per second, correlating historical failures with real-time anomalies. Food processing clients achieved 92% mean time between failure (MTBF) improvement through virtual commissioning of pallet patterns.

Smart Factory Interfacing

MES integration requires OPC UA communication with 15ms cycle times for production reporting. Standardized data models capture OEE metrics:

– Palletizing efficiency (actual vs. theoretical cycles)

– Gripper changeover duration

– Energy consumption per pallet

AGV synchronization employs traffic management algorithms that optimize docking sequences. Yanmao’s API enables AGV fleets to request pallet pickup within 3 seconds of layer completion. 5G edge computing reduces wireless latency to 8ms – critical for multi-AGV facilities.

Industry-Specific Validation:

– Beverage: CAN bus integration with filler CIP cycles prevents palletizer starvation

– Pharma: Electronic batch records auto-populate pallet RFID tags per 21 CFR Part 11

– E-commerce: Vision-guided parcel orientation adjusts for variable-sized shipments