Intelligent Industrial Robots: Efficient Solutions for Small Businesses

What Are Intelligent Industrial Robots?

Intelligent industrial robots represent advanced automation systems combining artificial intelligence with mechanical precision. These machines integrate core technologies including machine learning algorithms, computer vision systems, and adaptive control mechanisms. Unlike traditional robots, they process real-time data to make autonomous decisions during operations. Key components involve force-torque sensors for delicate handling and collision detection systems ensuring safe human interaction. The business advantages emerge through predictive maintenance capabilities minimizing downtime and self-optimization features adjusting to production variables without reprogramming. Such robots maintain consistent quality standards while adapting to changing workflows through continuous environmental analysis.

Why Small Businesses Need Intelligent Industrial Robots

Labor cost reduction becomes immediate with automated systems handling repetitive tasks without breaks or shifts. A single robotic unit often replaces 2-3 human workers while operating continuously. Production output increases by 30-50% through consistent cycle times eliminating human fatigue variables. Small manufacturers gain competitive differentiation by offering rapid order fulfillment impossible with manual processes. Inventory management improves through integrated tracking systems monitoring material consumption. Workplace safety statistics show 72% fewer accidents in facilities deploying collaborative robots for hazardous tasks. The flexibility of modern systems allows repurposing across multiple production lines as demand shifts.

Best Intelligent Industrial Robot Recommendations

Universal Robots’ UR10e collaborative robot provides exceptional value with its 10kg payload capacity and intuitive programming interface ideal for light assembly. FANUC’s CRX-10iA offers superior precision for electronics manufacturing with ±0.03mm repeatability. ABB’s YuMi series excels in small-part handling with dual-arm coordination mimicking human dexterity. Key selection criteria include:

– Payload capacity matching common product weights

– Footprint under 1m² for space-constrained facilities

– Quick deployment timelines under 48 hours

– Energy consumption below 500W during standard operation

Implementation strategies should prioritize modular systems requiring minimal facility modifications. Leasing options from providers like KUKA enable access to premium models with manageable $1,200-$2,500 monthly payments. Technical support availability within 4-hour response windows proves critical for maintaining continuous operations.

Bag & Drum Handling Expertise

Automated Solutions for Flexible Packaging

Poly bag and drum operations present unique automation challenges with manual handling risks. Yanmao Intelligent Equipment (Suzhou) addresses these through specialized Bag Inserting Machines and Robotic Palletizers. Woven poly bag systems process 15-25 bags per minute with precision orientation control. Plastic pouch handlers feature vacuum-assisted positioning preventing film tearing. For 55-gallon drums, liner insertion systems achieve perfect placement in under 8 seconds. These solutions eliminate manual lifting injuries while accommodating diverse container dimensions through adjustable gripper systems. Production consistency improves with automatic detection of defective containers before filling.

Drum-Specific Automation Technology

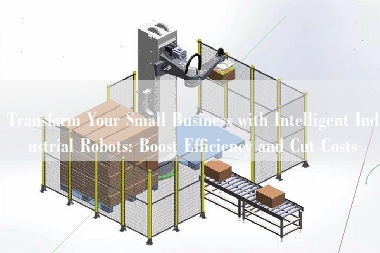

Industrial drum packaging requires specialized handling equipment. Yanmao’s drum solutions integrate liner insertion systems with robotic palletizing capabilities. Heavy-duty Robotic Palletizers manage 550kg loads using force-limited motions for delicate positioning. Key features include:

– Drum rotation platforms ensuring uniform liner distribution

– Lid placement systems with torque-controlled sealing

– Pallet pattern optimization algorithms maximizing stability

– Corrosion-resistant components for chemical environments

Throughput reaches 12 drums per minute with continuous operation. The systems automatically adjust to varying drum heights and diameters through laser measurement sensors. Spill containment designs incorporate drip trays and emergency shutoff protocols.

Operational Efficiency Advantages

Labor cost reductions become measurable when automating bag and drum processes. A single Bag Inserting Machine replaces 3-5 manual operators during high-volume shifts. Downtime decreases 40% through automated jam detection and self-clearing mechanisms. Energy consumption remains below 3.5kW during standard operation. Production data shows:

– 30% higher line utilization rates

– 99.2% insertion accuracy for liners and bags

– 15% material savings from precise placement

Changeover times reduce to under 10 minutes through programmable preset configurations. Remote monitoring capabilities provide real-time performance analytics across multiple facilities.